What is a PET Blow Molding Machine?

A PET (polyethylene terephthalate) blow molding machine manufactures plastic bottles and containers from PET preforms. Using heat and air pressure, these machines mold preforms into desired shapes, making them essential for industries like beverages, pharmaceuticals, personal care, and household products. PET blow molding machines are valued for producing lightweight, durable, and recyclable containers, meeting modern packaging needs.

Key Features of PET Blow Molding Machines

1.High Precision: Ensures consistent quality and accurate bottle dimensions.

2.Energy Efficiency: Advanced models minimize energy consumption and maximize output.

3.Speed and Productivity: Capable of producing up to 24,000 bottles per hour.

4.Flexibility: Creates a variety of bottle sizes and shapes.

5.Environmental Friendliness: Supports sustainable practices through recyclability and reduced material waste.

Types of PET Blow Molding Machines

1. Injection Stretch Blow Molding (ISBM) Machines

·Combines injection molding and blow molding to create high-clarity, strong bottles. Commonly used for water, soda, and cosmetic containers.

2. Extrusion Blow Molding (EBM) Machines

·Uses a molten plastic tube (parison) and air pressure to form shapes. Ideal for specialty containers requiring intricate designs.

3. Rotary Blow Molding Machines

·Operates continuously for high-speed, mass production. Suitable for beverages like water and soft drinks.

4. Linear Blow Molding Machines

·Processes preforms in a linear layout, offering flexibility for medium-scale production.

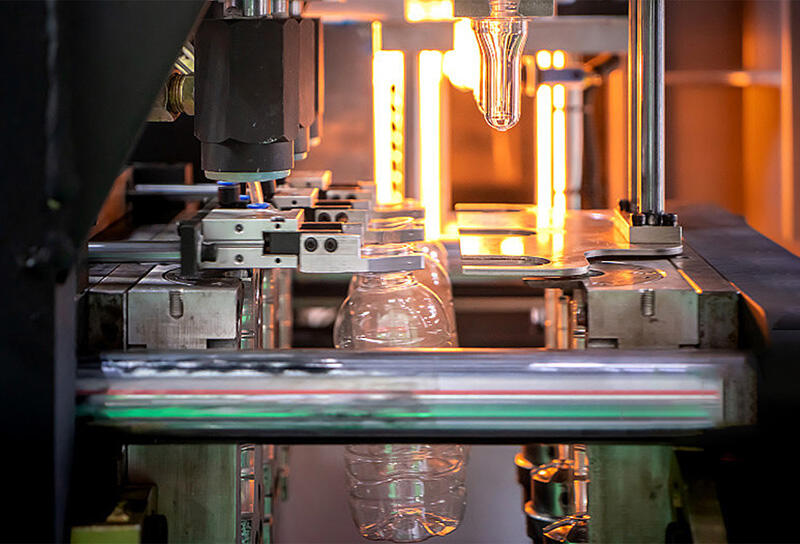

Components of a PET Blow Molding Machine

1.Preform Feeder: Loads preforms into the machine.

2.Heating Unit: Warms preforms for molding.

3.Stretching and Blowing Unit: Shapes bottles using stretching and air pressure.

4.Mold: Defines the bottle’s final shape.

5.Control System: Ensures precise operations and real-time monitoring.

Advantages of PET Blow Molding Machines

1.Cost Efficiency: Reduces material costs with lightweight bottles.

2.Durability: Produces impact-resistant bottles for various uses.

3.Customization: Adapts to diverse designs and sizes.

4.High Throughput: Delivers consistent, high-speed production.

Conclusion

PET blow molding machines drive modern packaging by offering efficiency, flexibility, and sustainability. Continuous advancements

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy