Semi Auto 2 Cavity Hot Filling PET Bottle Blowing Machine Stretch Blow Molding Machine for 330ml Bottles

- Overview

- Related Products

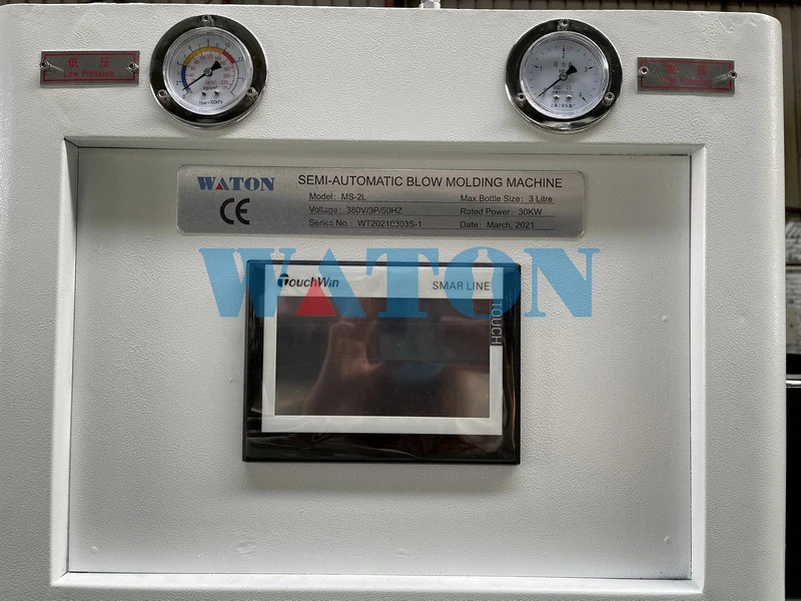

If you're in the market for a hot filling PET bottle blowing machine that is efficient and easy to operate, look no further than the Semi Auto 2 Cavity Hot Filling PET Bottle Blowing Machine Stretch Blow Molding Machine from renowned brand, WATON. This machine is specifically designed for the production of 330ml bottles, making it perfect for any beverage manufacturer looking to streamline their production process.

One of the best features of the Semi Auto 2 Cavity Hot Filling PET Bottle Blowing Machine is its semi-automatic operation. This means that it requires minimal human input and can produce high-quality bottles at a fast rate. The machine is equipped with advanced technology that ensures consistent performance, making it reliable and efficient. This machine is built to meet the needs of any manufacturer, regardless of their industry or production volume.

The machine is easy to operate, with a user-friendly interface that requires only minimal training to master. It is also designed with safety in mind, with features like an emergency stop button and protective covers. The Semi Auto 2 Cavity Hot Filling PET Bottle Blowing Machine is built to last, with high-quality materials that are scratch-resistant and long-lasting.

One of the key advantages of this machine is its hot filling capability. This means that it can produce bottles that are suitable for hot-fill beverages like juices, teas, and other drinks. The bottles produced by this machine can withstand high-temperature filling and are built to maintain their shape and quality over time, which is essential for any beverage manufacturer.

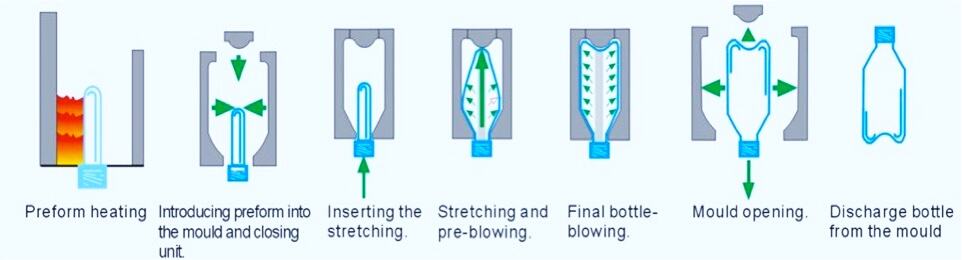

Another notable feature of the Semi Auto 2 Cavity Hot Filling PET Bottle Blowing Machine is its stretch blow molding technology. This process ensures that the bottles produced are of consistent quality, with smooth finishes and uniform wall thickness. The technology also minimizes waste, making it a cost-effective option for any manufacturer

Models |

MS-2L |

Theoretical Capacity |

1600-1800 BPH |

Mold Cavities |

2 |

Neck Size |

18-38mm |

Max. Volume |

2000ml |

Advantages |

1. Pre-blow Function improve bottle quality

2. Affordable price

|

Models |

MS-2L |

MS-2L4 |

MS-5L-1 |

MS-5L-2 |

MS-20L |

||

Theoretical Capacity(BPH) |

800-1,000 |

1,400-2,000 |

350-400 |

700-800 |

60-240 |

||

Mold Cavities |

2 |

4 |

1 |

2 |

1 |

||

Bottle |

Max. Neck Size |

100mm |

100mm |

100mm |

100mm |

100mm |

|

Max. Volume |

2000ml |

2000ml |

5000ml |

5000ml |

20000ml |

||

Max. Diameter |

105mm |

105mm |

180mm |

180mm |

280mm |

||

Max. Height |

330mm |

330mm |

350mm |

350mm |

500mm |

||

Main Machine Size |

1680*950*1980mm |

1 main machine |

1900*650*1580mm |

1900*800*1580mm |

2500*800*1900mm |

||

Heater Size |

1650*700*1700mm |

1 heater |

2100*600*1350mm |

2100*600*1350mm |

2600*700*1580mm |

||

Main Machine Weight |

1500KGS |

2500KGS |

1700KGS |

1700KGS |

2400KGS |

||

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3. Working time: 8:30am ~5:30pm, Monday to Saturday.

4. Your business relationship with us will be confidential to any third party.

5. Good after-sales service offered, please get back to us if you got any questions

Our Services & Strength

Q1: Where is your factory located? How can I visit there

A1: Our factory is located in Shangnian Industrial Area, Huang Yan, Taizhou City, Zhejiang Province, China. All our clients, from home or abroad, are warmly welcome to visit us! From Shanghai to our city, it takes 3.5 hrs by train, 45 mins by air

Q2: How long is the warranty period

A2: All of products have two years warranty

Q3: How can I install my machine when it arrives

A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines

Q4: How long is the delivery time

A4: Under normal conditions, products are delivered within 45 working days

Q5: Where is the Shipping departure port

A5: Ningbo or shanghai port

Q6: What’s the payment

A6: T/T, L/C, Western Union, paypal

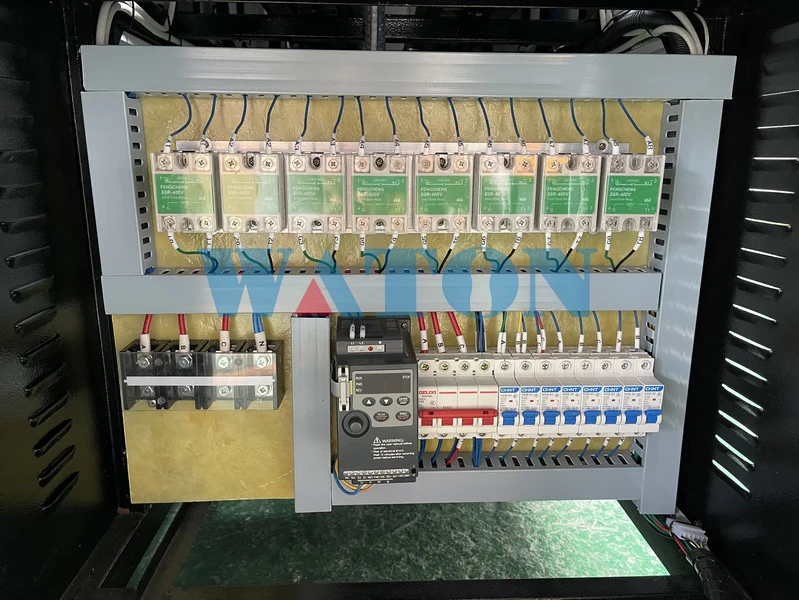

Q7: What are your main brand of electrical components

A7: Main parts in the products come from world famous manufacturers such as Mitsubishi, Schneider, Omron etc

Q8: Which country do you export your machines already

A8: We have exported Blow Molding Machine to USA, Canada, Australia, Mexico, Russia, Thailand, Indonesia, Vietam, Africa, the Middle East area etc

Q9. What products does your company offer by yourself

A9: We are specialized in PET Blow Molding Machine, PET Blow Mold, hot-runner PET Preform Mold

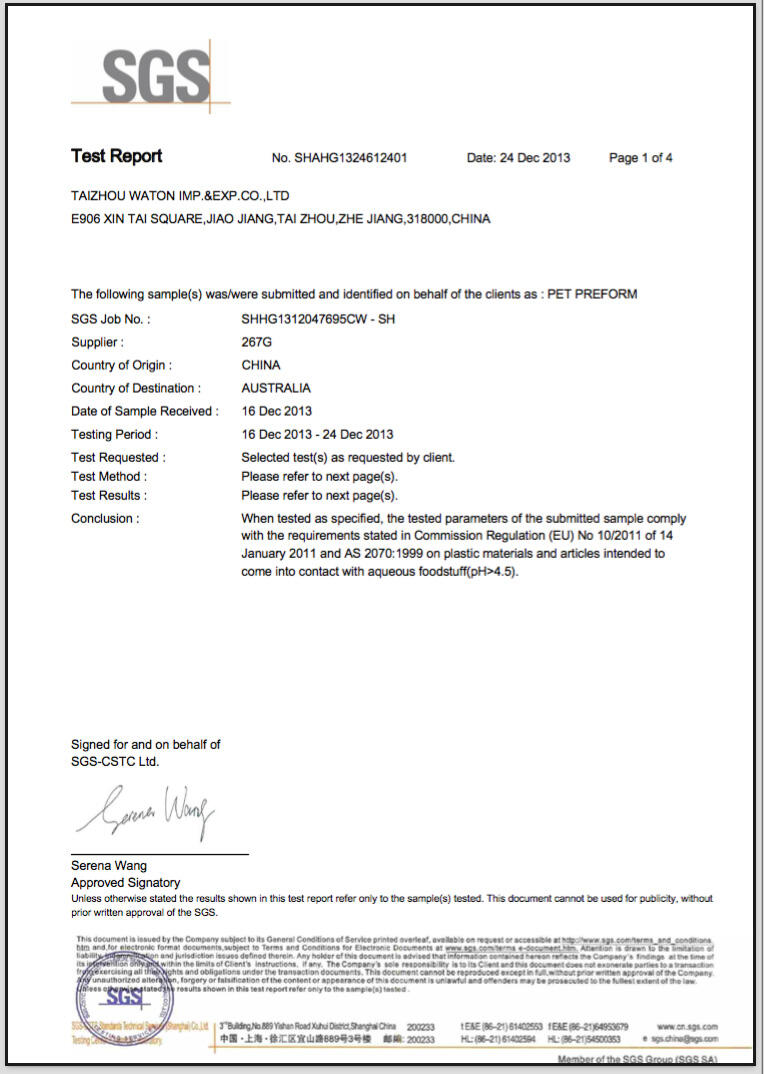

Q10: How about the quality of machine

A10: WATON have been focusing on quality issues, quality control from beginning to the end, and we will test machine strictly before packing and delivery.