- Overview

- Related Products

Description of application effect

If you're looking for the right Plastic Injection Molding Machine, you've come to the right place. WATON is a trusted brand that produces top-quality machines that can effectively create plastic parts for almost any use.

Manufactured by WATON, these injection molding machines are designed to be efficient and reliable, offering a robust solution that can handle high volume production. These machines make it possible to produce everything from small plastic toys to large automotive parts, using a range of plastics including ABS, PP, and nylon.

With WATON’s injection molding machines, you can control the temperature and pressure of the molding process to ensure that the plastic is properly melted and molded. You can adjust the machine's settings to produce different textures, shapes, and thicknesses, allowing for greater customization of your products.

WATON’s Plastic Injection Molding Machines are designed with safety in mind. They feature advanced safety features that prevent accidents and protect workers. The machines are easy to operate, with intuitive controls that make it possible for even novice operators to start producing high-quality plastic parts quickly.

These machines are built to last, with durable components that can withstand daily wear and tear. WATON produces machines that are made from high-quality components, ensuring that they are built to withstand even the toughest manufacturing environments.

WATON’s Plastic Injection Molding Machines come in a range of sizes and configurations, making it easy to find the right machine for your specific needs. Whether you're a small business looking to start production or a large corporation that needs to ramp up its manufacturing capabilities, WATON has a machine that can meet your requirements

Models |

WT260 |

Screw Diameter |

70mm |

Screw L:D ratio |

24 L/D |

Shot Volume |

1154 cm3 |

Injection Stroke |

300mm |

Max Screw Speed |

120 r/min |

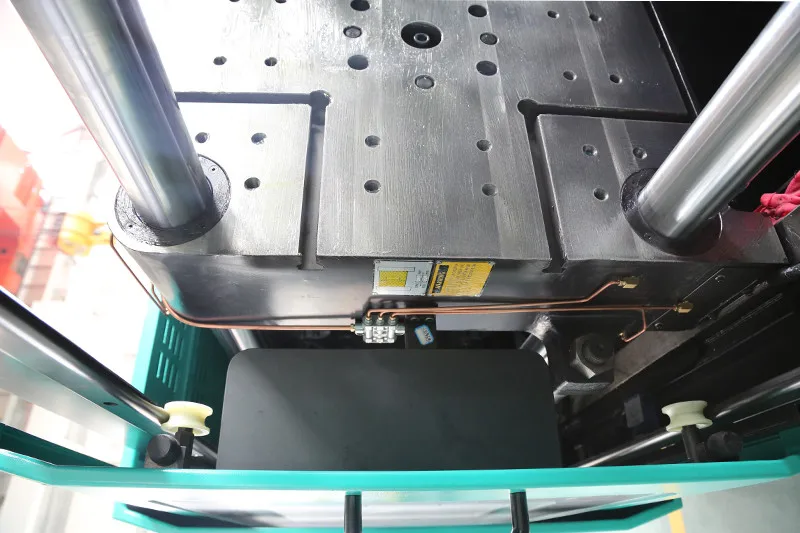

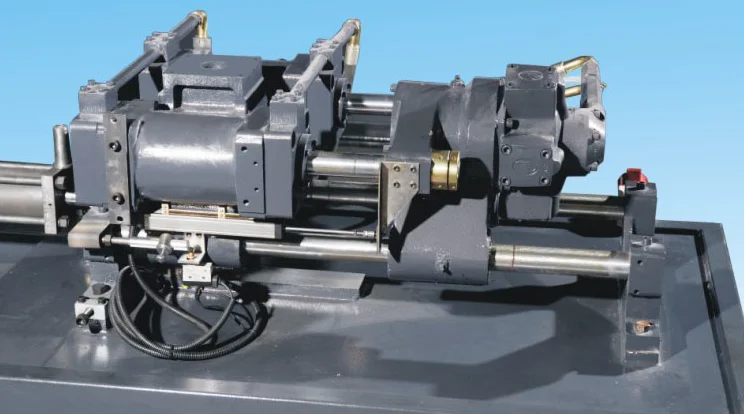

▶Short and forceful double-cylinder injection system ensures the steady injection motions;

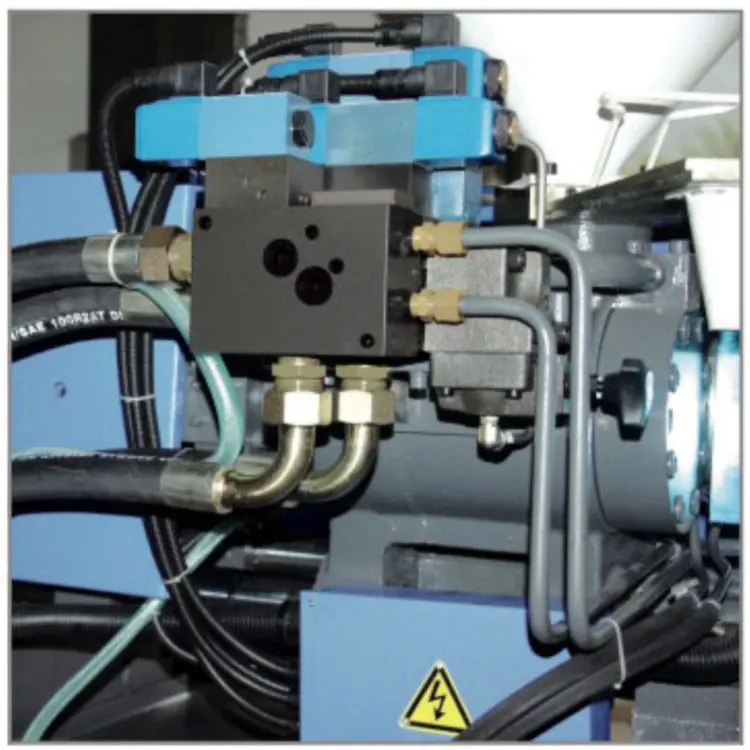

▶PID temperature control in combination of high precision electronic ruler, ensure the quality of formed products and production continuation;

▶Functions of auto material preparation, drooling proof, and anti cold start relay ensure the high efficient, simple and safe operation

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3. Working time: 8:30am ~5:30pm, Monday to Saturday.

4. Your business relationship with us will be confidential to any third party.

5. Good after-sales service offered, please get back to us if you got any questions

Our Services & Strength

Q1: Are you a manufacturer or trading company

A: We are the manufacturer from Taizhou, so we can offer you the best quality and best price of the machine.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines

A2: We offer you high quality machines with high quality after-service. Also we have two year warranty of the spare parts, free of charge.

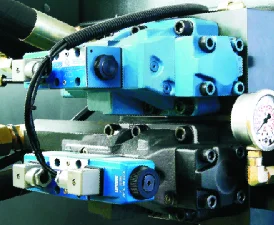

Q3: What is the advantage of servo control

A3: 1. Precision

2. Fast reaction, make high speed possible 3. Low power consumption 4. Low noise 5. hygiene, without oil leakage problemQ4: Do you have technical support after we purchased your machines

A4: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q5: What after-sales service your company offers

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese. 3. Working time: 8:30am ~5:30pm, Monday to Saturday. 4. Your business relationship with us will be confidential to any third party. 5. Good after-sales service offered, please get back to us if you got any questionsQ6: Can I visit your factory and send team for learning and inspect

A6:Yes, sure. We will do our best to teaching you how to use the machine.welcome to visit our factory!

Q7: What your advantages are

A7: 1. Stable running machines with newly technology, competitive price;

2. top rank technical support 3. Best and prompt serviceQ8: Where is your factory located? How can we visit there

A8: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q9: What is your terms of packing

A9: Because of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

Q10: When Can I get my machine after I paid

A10: The delivery time is about 30-45 working days