High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine / Bottle Blow Molding Machine Price

- Overview

- Related Products

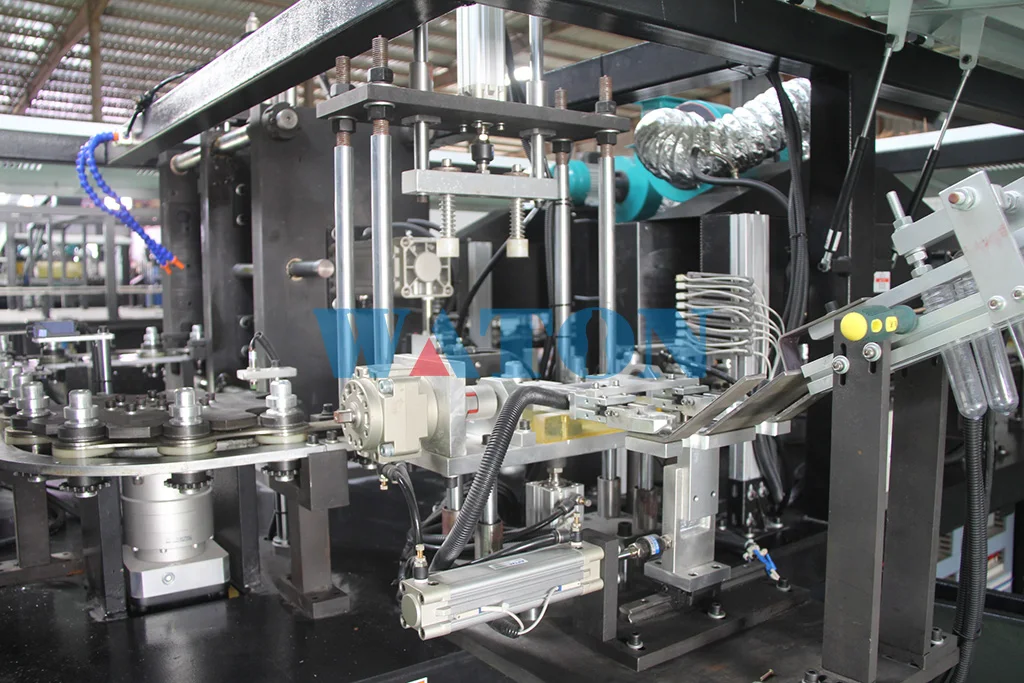

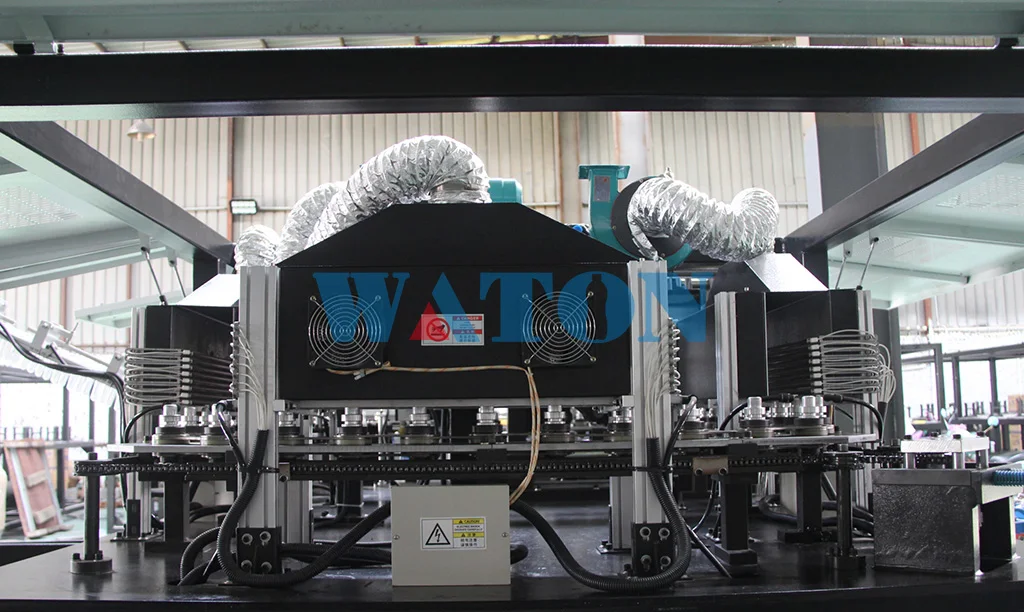

Introducing, the WATON’s High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine - the ultimate solution for businesses looking to increase production of plastic bottles. This machine is designed to be efficient, durable and user-friendly, making it the perfect addition to any production line.

With a high speed of up to 1500 bottles per hour, the WATON’s High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine ensures that your business can produce a large quantity of plastic bottles in a short amount of time, saving you money and boosting your productivity. In addition to its speed, the machine is accurate and precise, ensuring that your bottles are of consistently high quality.

The WATON’s High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine has a simple and user-friendly control panel which makes operating it easy even for workers with minimal experience with machines. All production processes are automatic, which minimizes the risk of errors and leads to production of perfect bottles consistently.

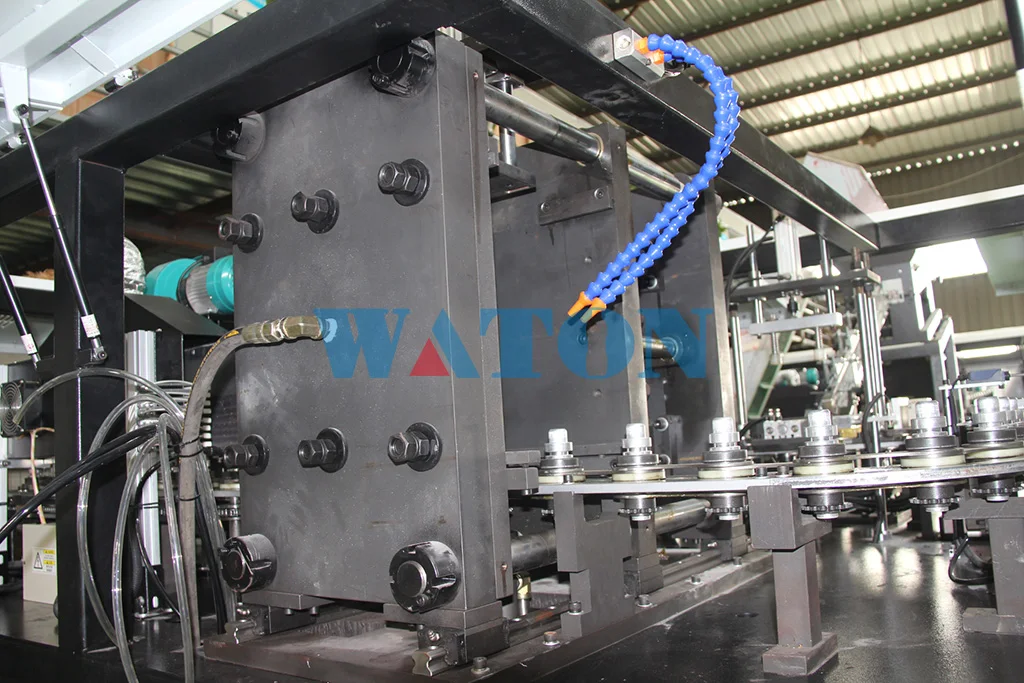

This machine is constructed from high-quality materials that are strong, durable and designed for longevity. It is designed to withstand harsh working environments and perform efficiently even in the most challenging of circumstances. Its compact size and smart design makes it easy to install and set up, saving you time and effort.

Another great feature of the WATON’s High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine is its energy-saving design and low power consumption capabilities. This helps reduce your business's energy bills, making it an even more cost-effective solution to your plastic bottle manufacturing needs.

In terms of price, the WATON’s High Speed Automatic Pet Plastic Bottle Making Stretch Blow Molding Machine is extremely competitive. It is an affordable option for businesses that require high-quality and reliable machines without breaking the bank

Models |

ECO2L |

Theoretical Capacity |

1800-2400BPH |

Mold Cavities |

2 |

Neck Size |

18-38mm |

Max. Volume |

2000ml |

Advantages |

1. Using touch screen, easy to operate, save space

2. Sstable performance

3. Far away from Heating Area, safe

|

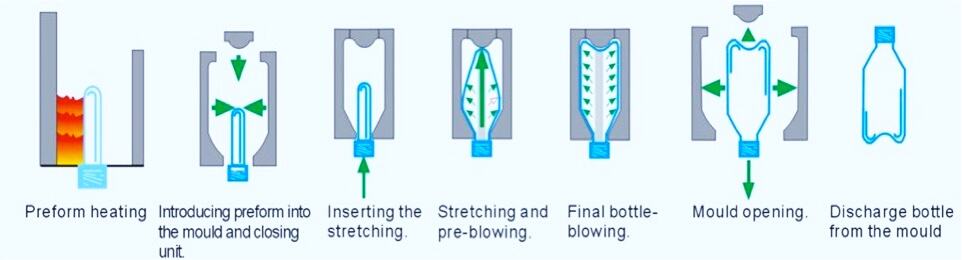

by WATON MACHINERY technical team, with feature economic, fast, convenient. It can make different kinds of PET package for water, edible oil, juice, wine, cosmetics, etc. It can make max. 2 Litre bottle

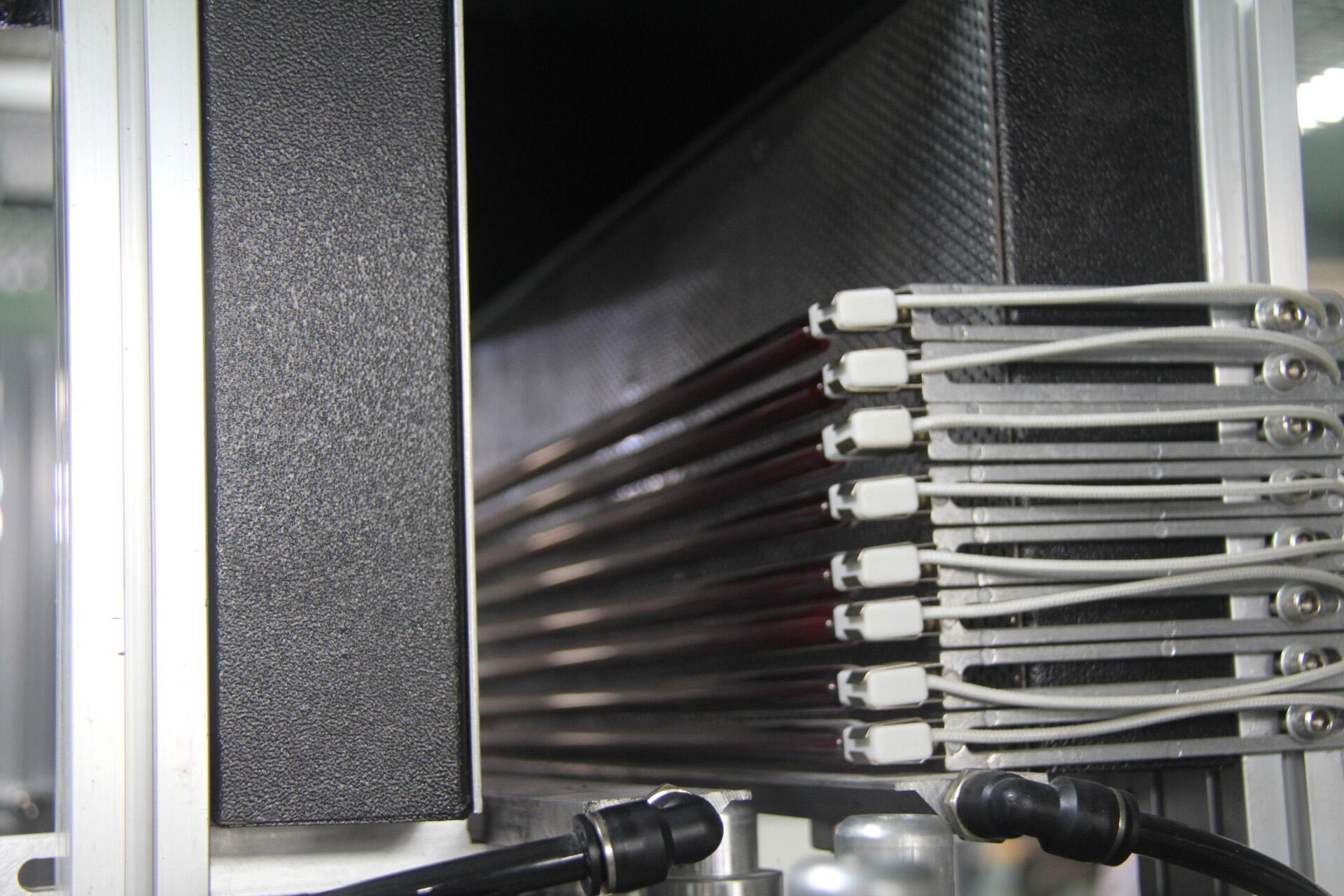

a. Use the most advanced high frequency Infrared Lamp, increase heating efficiency 30%-50%

b. Each layer of lamp are separately controlled, with assistant ruler on machine

c. Intelligent temperature control system.

d. Preform self-rotation System, ensure every side of every preforms are heated evenly, which ensure quality of blown bottle. thickness up to 4.5mm

e. Neck Cooling in Oven

f. Preform Necks are cooled by recycling water, which avoid neck deformation

Models |

ECO-2 |

ECO-4S |

ECO-4L |

ECO-6S |

ECO-6L |

||

Theoretical Capacity(BPH) |

1,800-2,400 |

4,600-5,000 |

3,600-4,500 |

6,000-7,000 |

5,000-6,000 |

||

Mold Cavities |

2 |

4 |

4 |

6 |

6 |

||

Bottle |

Nick Size |

18-38mm |

18-38mm |

18-38mm |

18-38mm |

18-38mm |

|

Max. Volume |

2000 ml |

750 ml |

2000 ml |

750 ml |

2000 ml |

||

Max. Diameter |

105 mm |

69 mm |

105 mm |

69 mm |

105 mm |

||

Max. Height |

330 mm |

240 mm |

330 mm |

240 mm |

330 mm |

||

power |

Heater qty |

16pcs |

21pcs |

32pcs |

28pcs |

48pcs |

|

Heating Area |

2 |

3 |

4 |

4 |

6 |

||

Heating Power |

35KW |

46KW |

70KW |

62KW |

106KW |

||

Rated General Power |

37KW |

50 KW |

75KW |

65KW |

110KW |

||

High Pressure Air Consumption(m³/min) |

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

||

Main Machine Size |

3000 * 1800 * 2400 mm |

3300 * 2000 * 2200 mm |

4200 * 2100 * 2400 mm |

4200 * 2050 * 2200 mm |

5800 * 2150 * 2400 mm |

||

Main Machine Weight |

2500KGS |

3600KGS |

5000 KGS |

5500KGS |

7800KGS |

||

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3. Working time: 8:30am ~5:30pm, Monday to Saturday.

4. Your business relationship with us will be confidential to any third party.

5. Good after-sales service offered, please get back to us if you got any questions

Our Services & Strength

Q1: Where is your factory located? How can I visit there

A1: Our factory is located in Shangnian Industrial Area, Huang Yan, Taizhou City, Zhejiang Province, China. All our clients, from home or abroad, are warmly welcome to visit us! From Shanghai to our city, it takes 3.5 hrs by train, 45 mins by air

Q2: How long is the warranty period

A2: All of products have two years warranty

Q3: How can I install my machine when it arrives

A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines

Q4: How long is the delivery time

A4: Under normal conditions, products are delivered within 45 working days

Q5: Where is the Shipping departure port

A5: Ningbo or shanghai port

Q6: What’s the payment

A6: T/T, L/C, Western Union, paypal

Q7: What are your main brand of electrical components

A7: Main parts in the products come from world famous manufacturers such as Mitsubishi, Schneider, Omron etc

Q8: Which country do you export your machines already

A8: We have exported Blow Molding Machine to USA, Canada, Australia, Mexico, Russia, Thailand, Indonesia, Vietam, Africa, the Middle East area etc

Q9. What products does your company offer by yourself

A9: We are specialized in PET Blow Molding Machine, PET Blow Mold, hot-runner PET Preform Mold

Q10: How about the quality of machine

A10: WATON have been focusing on quality issues, quality control from beginning to the end, and we will test machine strictly before packing and delivery.