High Quality 1 Liter Bottle Making Machine Automatic 4 Cavity PET Oil Bottle Cosmetic Bottle Blowing Machine

- Overview

- Related Products

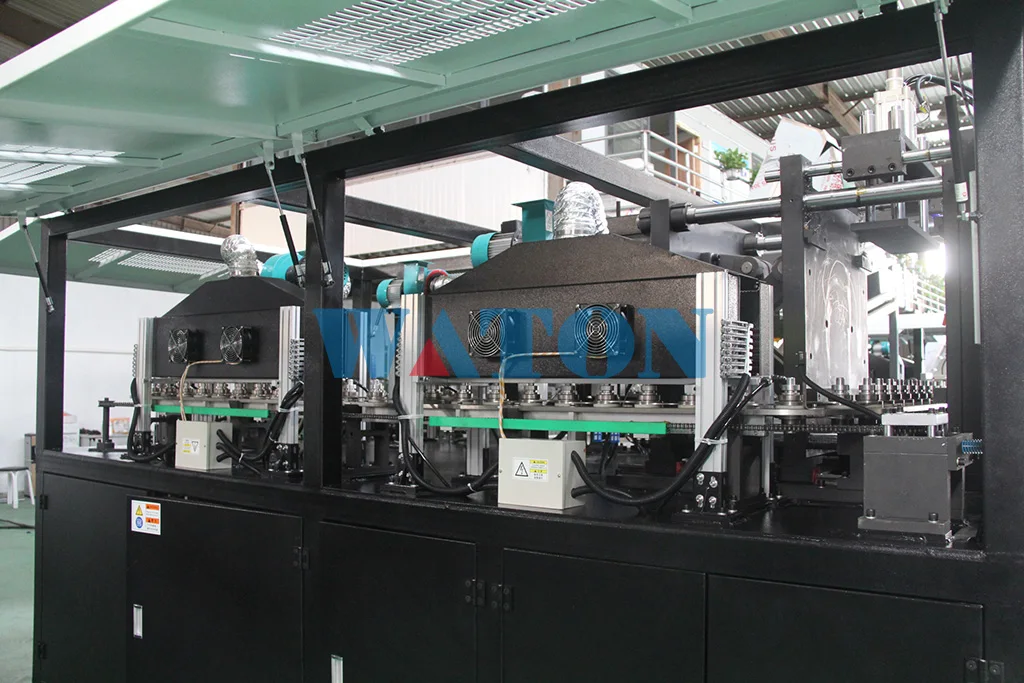

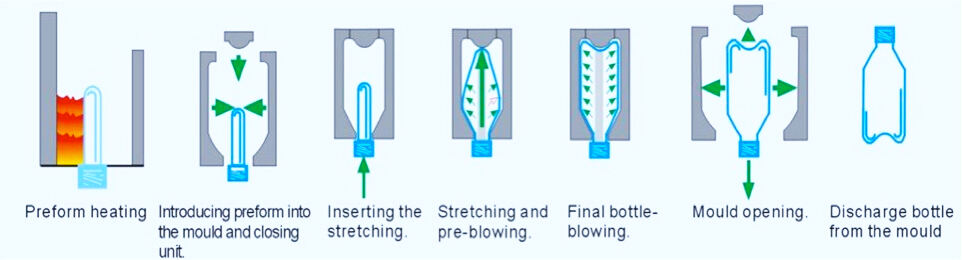

The WATON’s High Quality 1 Liter Bottle Making Machine Automatic 4 Cavity PET Oil Bottle Cosmetic Bottle Blowing Machine is a top-of-the-line product that delivers precise and efficient results. The machine is designed to produce high-quality bottles with a capacity of 1 liter and has an automatic 4 cavity system that makes it perfect for manufacturing cosmetic bottles, oil bottles, and other liquid storage bottles.

This machine is made of high-quality materials, ensuring its durability and longevity. It is easy to set up and operate, making it ideal for businesses of all sizes. The machine comes with a user-friendly interface and is equipped with advanced technology that ensures complete automation of the bottle-making process.

The WATON’s High Quality 1 Liter Bottle Making Machine Automatic 4 Cavity PET Oil Bottle Cosmetic Bottle Blowing Machine is perfect for businesses that require high volumes of bottles. With a production capacity of 4000 bottles per hour, it is ideal for businesses that require large quantities of bottles in a short period of time.

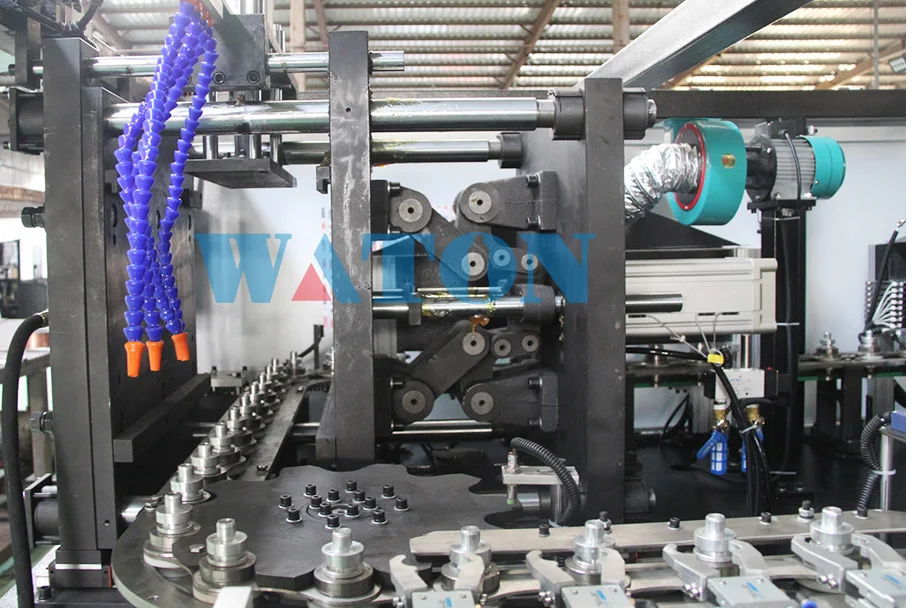

One of the key features of this machine is its 4 cavity system, which allows it to produce four bottles at the same time, making the production process more efficient and time-saving. The machine is also equipped with advanced cooling and heating systems that ensure the bottles are produced with high precision and accuracy.

This machine is tailor-made for businesses that require high-quality bottles for their products. Whether you are in the cosmetic industry or the oil industry, this machine is perfect for you. The WATON’s High Quality 1 Liter Bottle Making Machine Automatic 4 Cavity PET Oil Bottle Cosmetic Bottle Blowing Machine is designed to produce bottles that are of the highest quality, ensuring your products stand out on the market.

The machine is also equipped with an automatic lubrication system, which ensures that the moving parts of the machine are properly lubricated, reducing wear and tear. This feature also makes the machine more durable and long-lasting

Models |

ECO-4L |

Theoretical Capacity |

3600-4500BPH |

Mold Cavities |

4 |

Neck Size |

18-38mm |

Max. Volume |

2000ml |

Advantages |

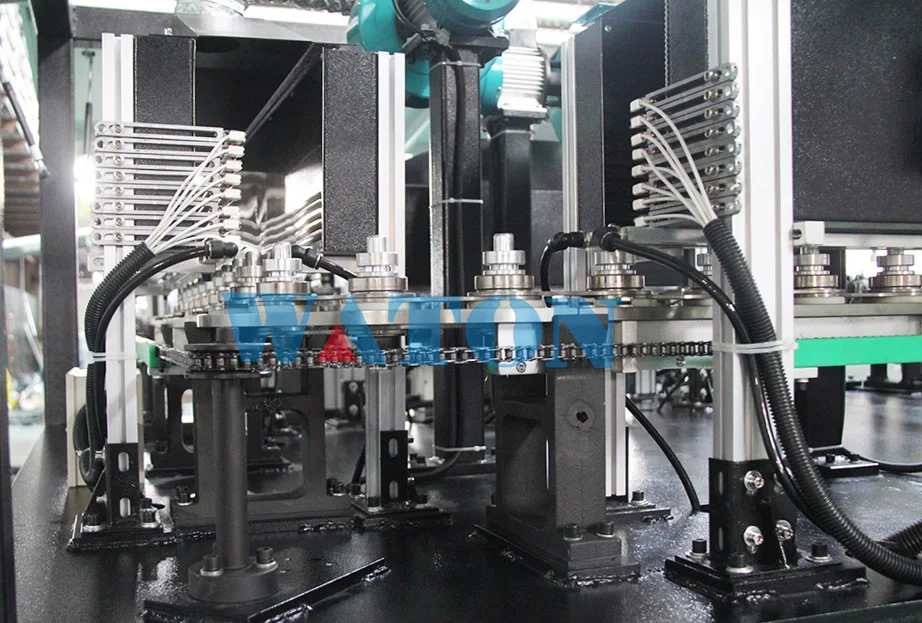

Preform Feeding System and Transfer System driven by servo motor, running at high accuracy and high speed. Combination of stable, energy-saving, eco-friendly |

Models |

ECO-2 |

ECO-4S |

ECO-4L |

ECO-6S |

ECO-6L |

||

Theoretical Capacity(BPH) |

1,800~2,400 |

4,600~5,000 |

3,600~5,000 |

6,000~7,000 |

5,000~6,000 |

||

Mold Cavities |

2 |

4 |

4 |

6 |

6 |

||

Bottle |

Neck Size |

18-38mm |

18-38mm |

18-38mm |

18-38mm |

18-38mm |

|

Max. Volume |

2000ml |

750ml |

2000ml |

750ml |

2000ml |

||

Max. Diameter |

105mm |

69mm |

105mm |

69mm |

105mm |

||

Max. Height |

330mm |

240mm |

330mm |

240mm |

330mm |

||

Power |

Heater qty |

16pcs |

21pcs |

32pcs |

28pcs |

48pcs |

|

Heating Area |

2 |

3 |

4 |

4 |

6 |

||

Heating Power |

35KW |

46KW |

70KW |

62KW |

106KW |

||

Rated General Power |

37KW |

50KW |

75KW |

65KW |

110KW |

||

High Pressure Air Consumption(m3/min) |

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

||

Main Machine Size |

3000*1800*2400mm |

3300*2000*2200mm |

4200*2100*2400mm |

4200*2050*2200mm |

5800*2150*2400mm |

||

Main Machine Weight |

2500KGS |

3600KGS |

5000KGS |

5500KGS |

7800KGS |

||

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3. Working time: 8:30am ~5:30pm, Monday to Saturday.

4. Your business relationship with us will be confidential to any third party.

5. Good after-sales service offered, please get back to us if you got any questions

Our Services & Strength

Q1: Are you a manufacturer or trading company

A: We are the manufacturer from Taizhou, so we can offer you the best quality and best price of the machine.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines

A2: We offer you high quality machines with high quality after-service. Also we have two year warranty of the spare parts, free of charge.

Q3: What is the advantage of servo control

A3: 1. Precision

2. Fast reaction, make high speed possible 3. Low power consumption 4. Low noise 5. hygiene, without oil leakage problem

Q4: Do you have technical support after we purchased your machines

A4: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q5: What after-sales service your company offers

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese. 3. Working time: 8:30am ~5:30pm, Monday to Saturday. 4. Your business relationship with us will be confidential to any third party. 5. Good after-sales service offered, please get back to us if you got any questions

Q6: Can I visit your factory and send team for learning and inspect

A6:Yes, sure. We will do our best to teaching you how to use the machine.welcome to visit our factory!

Q7: What your advantages are

A7: 1. Stable running machines with newly technology, competitive price;

2. top rank technical support 3. Best and prompt service

Q8: Where is your factory located? How can we visit there

A8: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q9: What is your terms of packing

A9: Because of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement

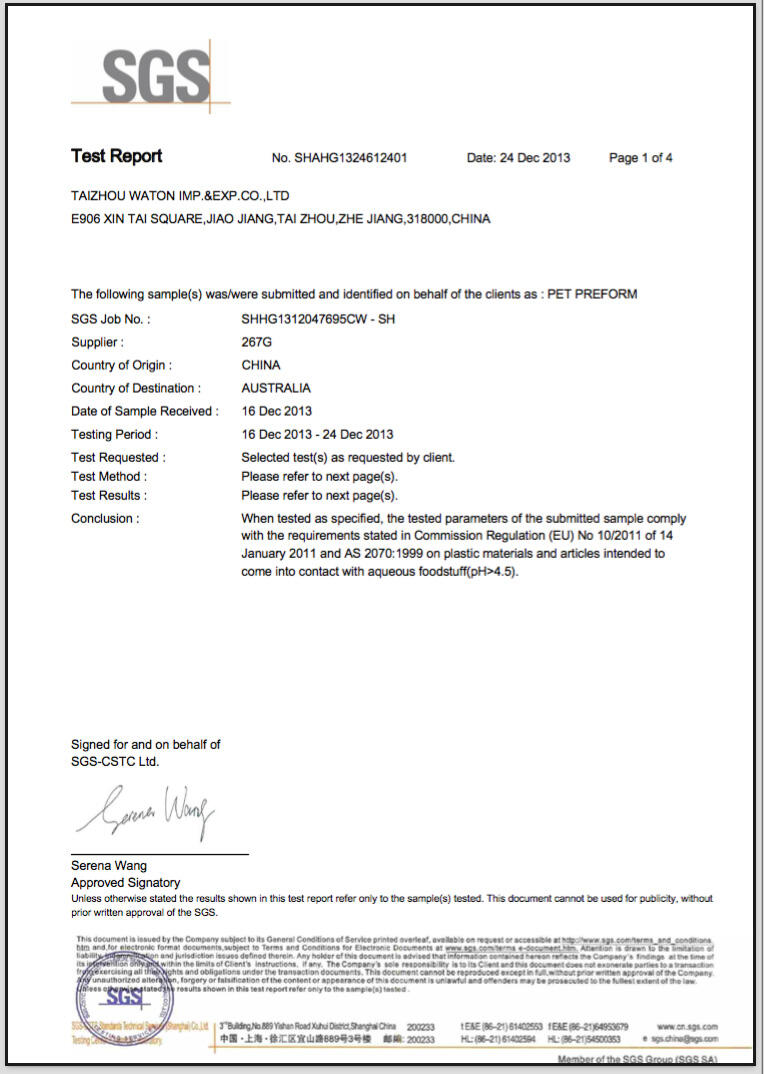

Q10:Does the machines & water dispenser have any certificates