- Overview

- Related Products

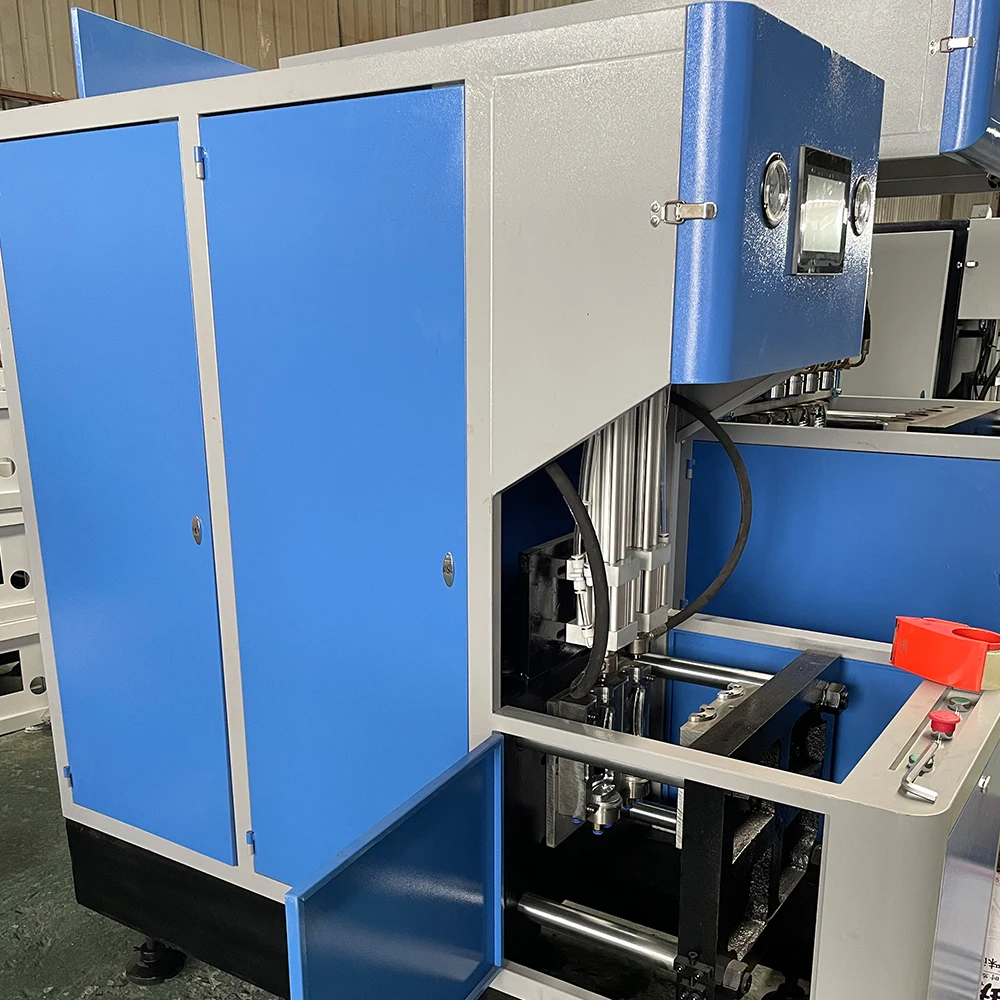

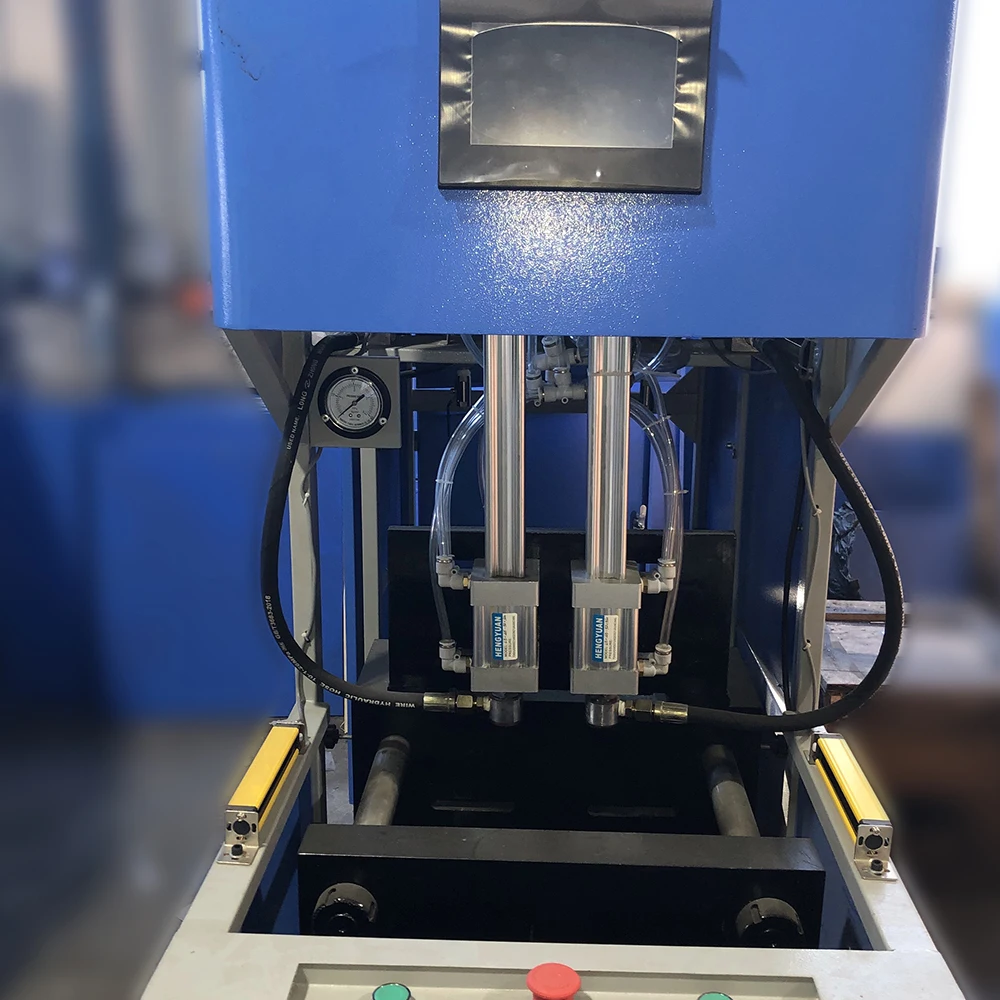

WATON is a leading brand in the market for manufacturing machines, and their latest product is the Factory Direct 750ml Plastic Bottle Manufacturing Machine. This world-class machine is designed to produce high-quality plastic bottles quickly and efficiently, making it an ideal choice for businesses that require a large quantity of bottles on a regular basis.

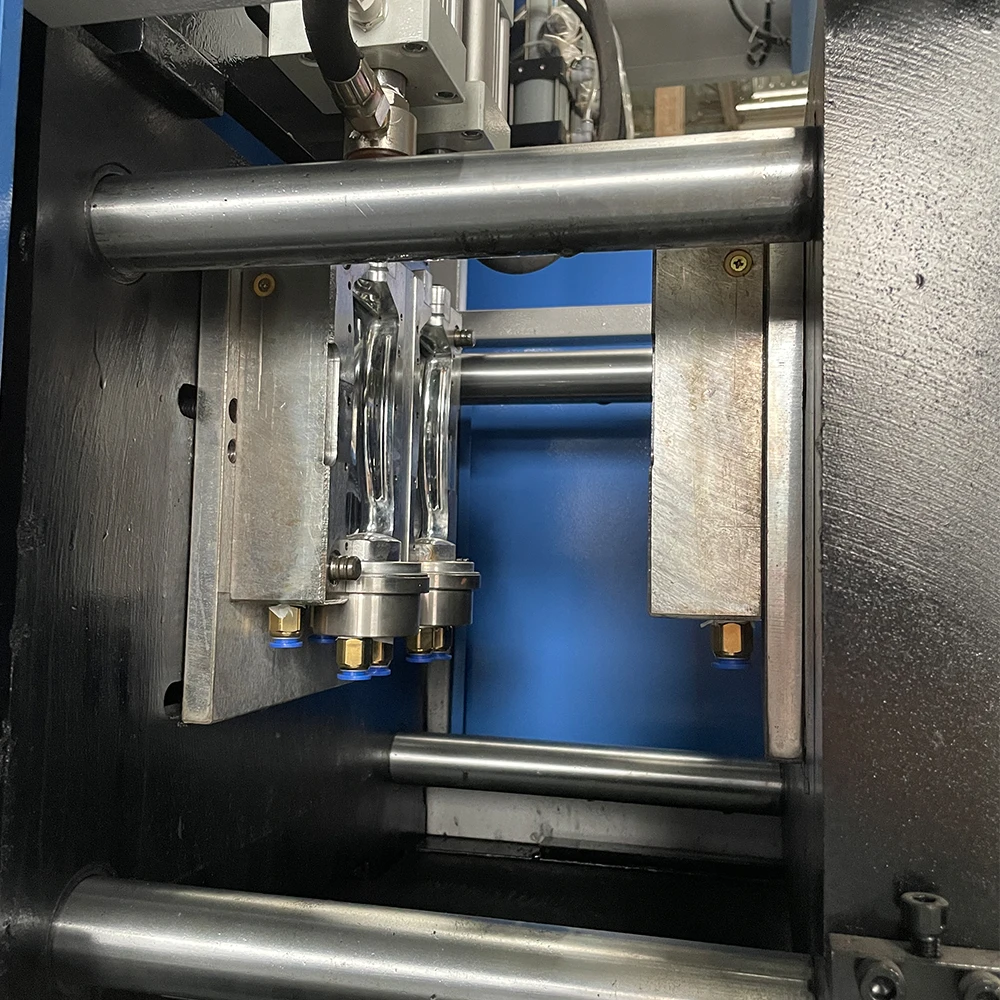

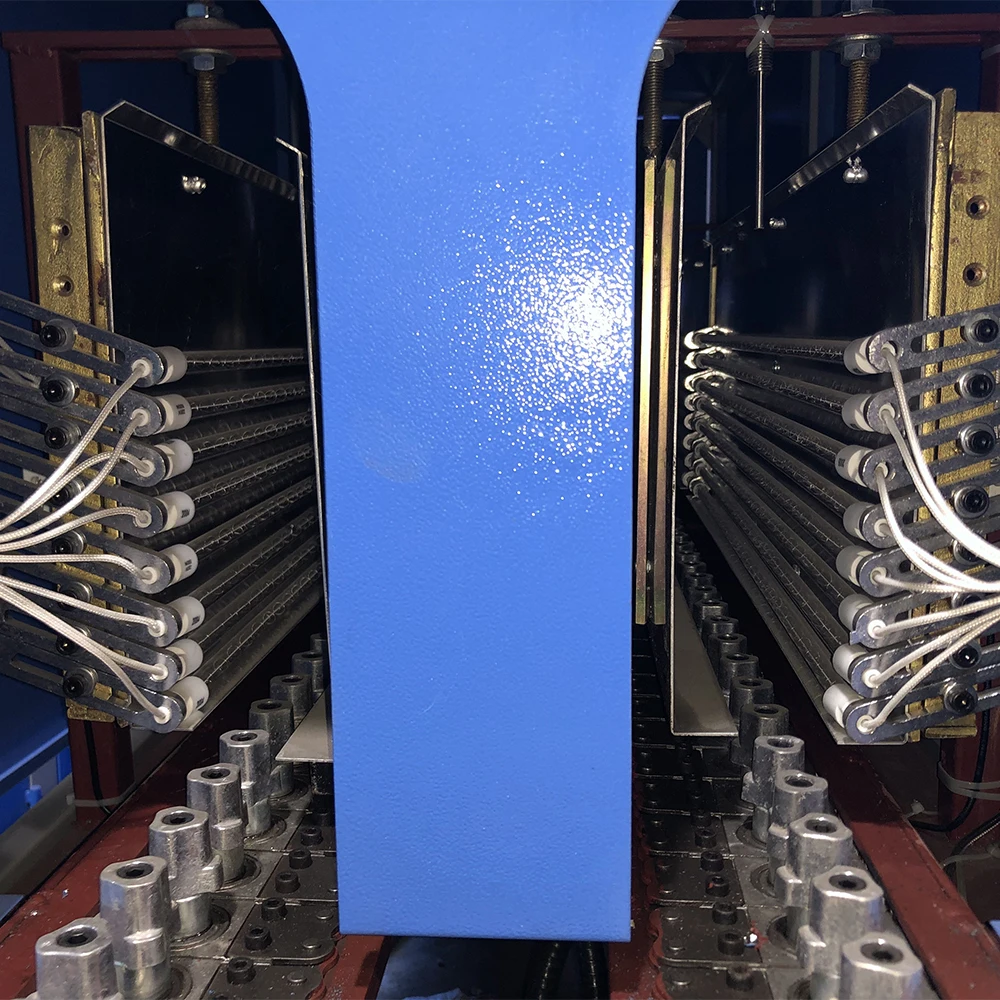

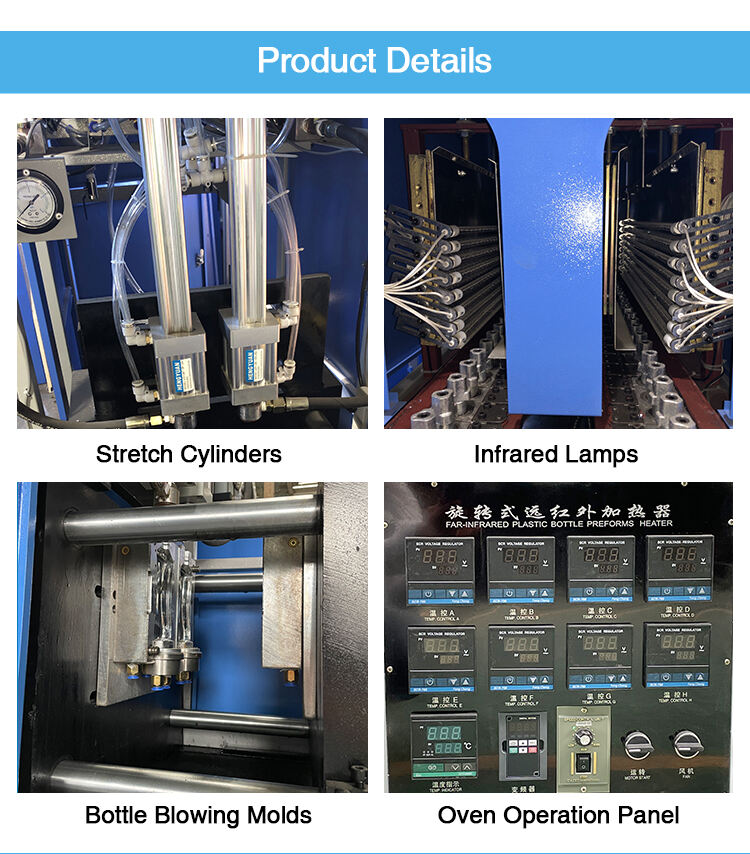

The process of manufacturing plastic bottles using this machine is simple and straightforward, thanks to its user-friendly interface. The process starts when the raw materials, mainly plastic pellets, are fed into the machine hopper. The pellets are then melted down and formed into a bottle shape using a mold. Once the bottle shape is formed, the machine will cool and solidify the plastic, resulting in a finished bottle that can be used for a wide range of purposes.

One of the key advantages of this bottle manufacturing machine is its versatility. It can be used to produce a wide range of plastic bottle sizes, up to 750ml. This makes it a suitable option for businesses that require different bottle sizes to cater to the needs of their customers.

The Factory Direct 750ml Plastic Bottle Manufacturing Machine is designed with durability in mind. It is made using high-quality materials, ensuring that it can withstand the rigors of regular use and last for many years. Additionally, the machine is designed to be easy to maintain, reducing the risk of breakdowns and production delays.

WATON's manufacturing machine is ideal for businesses that want to cut down on their production costs. The machine is designed to consume minimal energy while still delivering robust performance, resulting in significant savings on energy costs. Additionally, it has a high production rate, allowing businesses to produce more bottles within a shorter time.

Another significant advantage of this machine is its ability to create bottles with uniform shapes and sizes. This is important for businesses that want to maintain their brand image and ensure their products look professional. The machine is also equipped with advanced safety features, reducing the risk of accidents and injuries in the workplace

Machine Model |

MS-2L2 |

Production Capacity (BPH) |

700-1,000 |

Max. Bottle Size |

3000 ml |

Max. Bottle Diameter |

105 mm |

Max. Bottle Height |

360 mm |

Mold Cavity |

2 cavities |

Mold Clamping Force |

66.48 KN |

Mold Opening Stock |

270 mm |

Mould Thickness |

120-200 mm |

Mould Width X Height |

340 mm X 340 mm |

Preform Neck |

28-60 mm |

Preform Length |

-- |

Heating Power |

22 KW |

General Power |

25 KW |

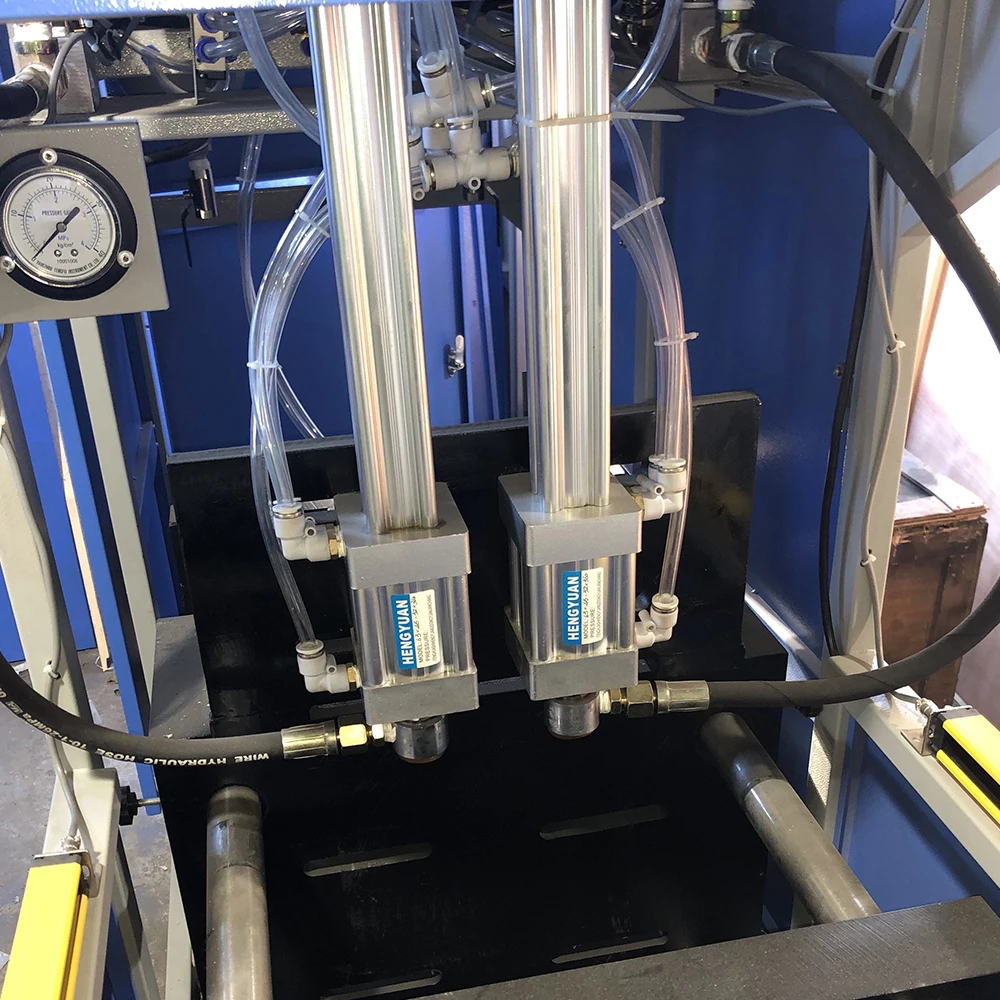

Blow Air |

2.6 – 3.0 MPa |

Drive Air |

0.8 – 1.0 MPa |

Main Machine Dimensions |

1650 * 650 * 1700 mm |

Oven Dimensions |

1700 * 850 * 1350 mm |

Main Machine Weight |

820 KGS |

Oven Weight |

250 KGS |

Q1: Where is your factory located? How can I visit there

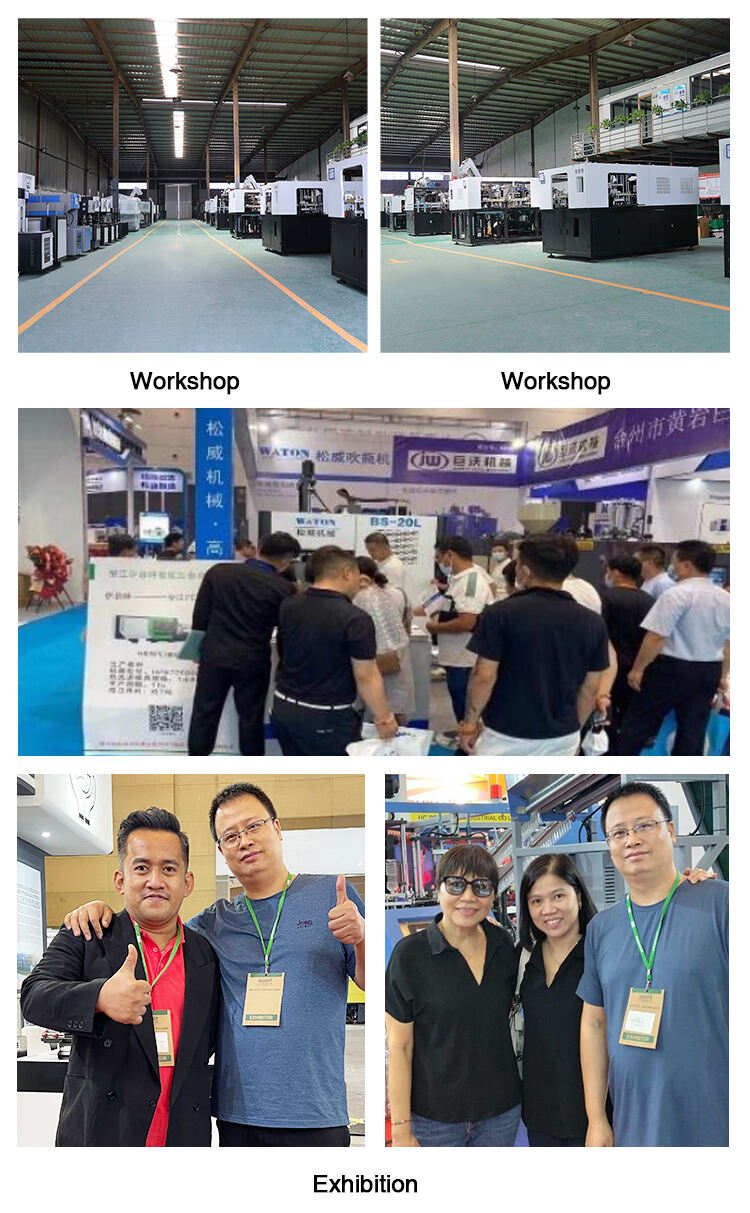

A1: Our factory is located in Shangnian Industrial Area, Huang Yan, Taizhou City, Zhejiang Province, China. All our clients, from home or abroad, are warmly welcome to visit us! From Shanghai to our city, it takes 3.5 hrs by train, 45 mins by air

Q2: How long is the warranty period

A2: All of products have two years warranty

Q3: How can I install my machine when it arrives

A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines

Q4: How long is the delivery time

A4: Under normal conditions, products are delivered within 45 working days

Q5: Where is the Shipping departure port

A5: Ningbo or shanghai port

Q6: What’s the payment

A6: T/T, L/C, Western Union, paypal

Q7: What are your main brand of electrical components

A7: Main parts in the products come from world famous manufacturers such as Mitsubishi, Schneider, Omron etc

Q8: Which country do you export your machines already

A8: We have exported Blow Molding Machine to USA, Canada, Australia, Mexico, Russia, Thailand, Indonesia, Vietam, Africa, the Middle East area etc

Q9. What products does your company offer by yourself

A9: We are specialized in PET Blow Molding Machine, PET Blow Mold, hot-runner PET Preform Mold

Q10: How about the quality of machine

A10: WATON have been focusing on quality issues, quality control from beginning to the end, and we will test machine strictly before packing and delivery.