ECO6-0.7L 7000BPH high speed plastic bottles full automatic pet blower making machine factory price

- Overview

- Related Products

Video Description

Products Description

ECO-6L Linear Automatic PET Blow Molding Machine is economical model which self-developed by WATON MACHINERY technical team, with feature economic, fast, convenient. It can make different kinds of PET package for water, edible oil, juice, wine, cosmetics, etc. It can make max. 2Litre bottle.

Model |

ECO6-0.7L |

Cavity Qty. |

6 cavity |

Max. Bottle Volume |

700ml |

Neck size |

18~38mm |

Theoretical Output |

6,000~7,000BPH(Bottles Per Hour) |

Max. Bottle Diameter |

69mm |

Max. Bottle Height |

250mm |

ADVANTAGE:

1.Upgrade to Servo Motor Drive:

Preform Transfer System: preforms horizontal movements are driven by Servo Motor which achieve high-speed positioning and smooth motion.

Mold Clamping System: Reaction time is reduced to 50% compared to traditional pneumatic model. Simple structure, no wear, longer use life.

Stretch System: Servo motor precisely controls the movement of stretch rods, and the accuracy can reach 1 mm. According to the adjustment of the bottle type, greatly improve the blowing adjusting process of flexibility, accuracy, improve the quality of products.

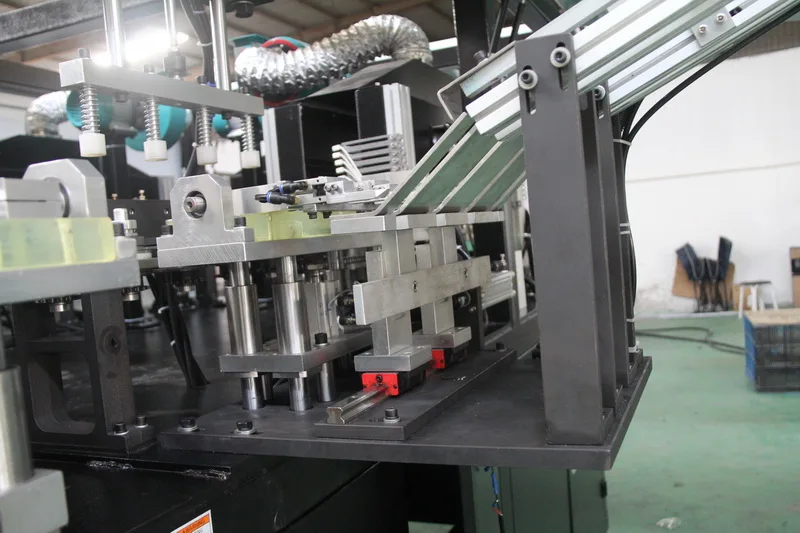

2.Mold fixing by Drawer Design.

Push the mold, fix the positioning screws. Mold changeover work can be easily done in half hour.

3.Efficiency Constant Temperature Oven:

a.The most advanced high frequency Infrared Lamp, increase heating efficiency 30%-50%.

b.Each layer of lamp are separately controlled, with assistant ruler on machine.

c.Intelligent temperature control system.

Temperature detector feedback to PLC automatically, PLC makes accurate judgment and then control circulation air in oven. It leads to constant temperature in Oven, free from voltage fluctuations and ambient temperature. It works when large ambient temperature difference (-28~45 ℃).

d.Preform self-rotation System, ensure every side of every preforms are heated evenly, which ensure quality of blown bottle.

e.Neck Cooling in Oven.

Preform Necks are cooled by recycling water, which avoid neck deformation.

4.Top quality parts, stable performance.

-HMI(Human Machine Interface), overall computer control, easy to operate.

-Independent operation station, more flexible to arrange operating positions. Far away from Heating Area, safe.

-Multi-point photoelectric detection, protect Positioning System, Clamping System and Stretch System.

Details Images

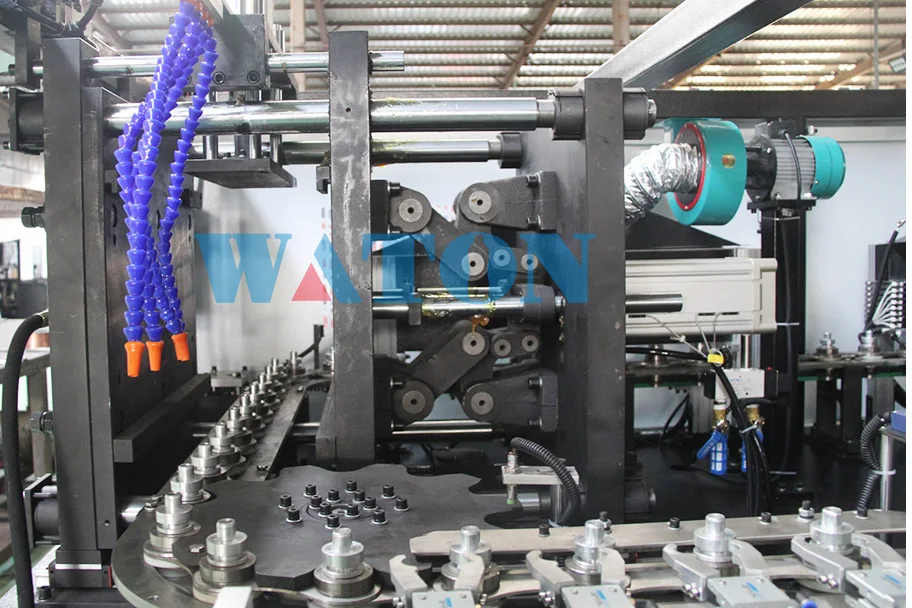

Preform Feeding Preform System

Mold Clamping System

Preform Transfer Servo

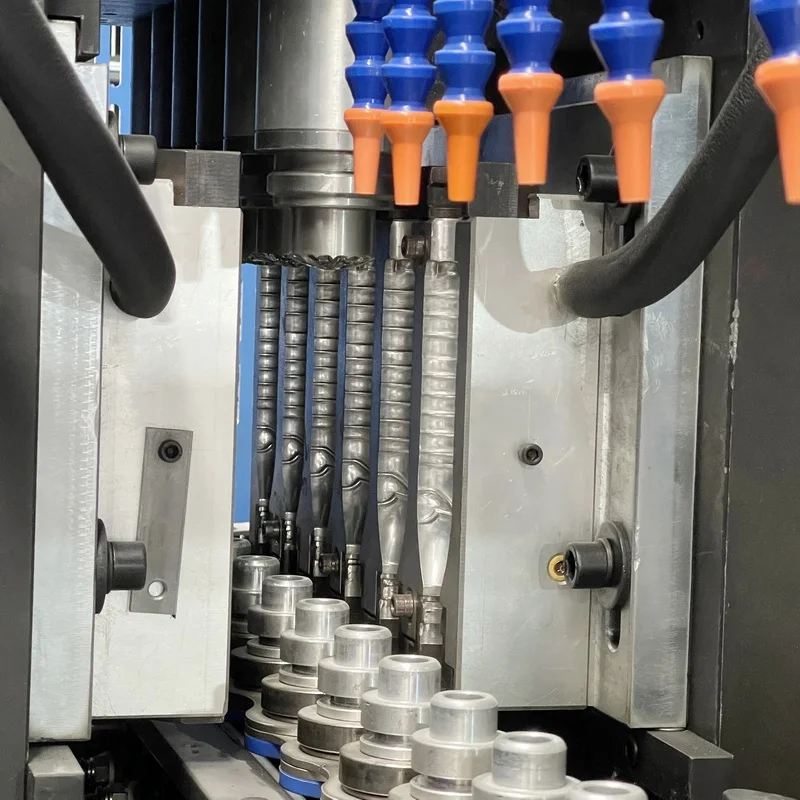

Stretch Cylinders

Advanced high frequency Infrared Heaters upgrade the heating efficiency 30%-50%

3 Heating Zones ensure preform efficient heated

Touch screen for easy operation

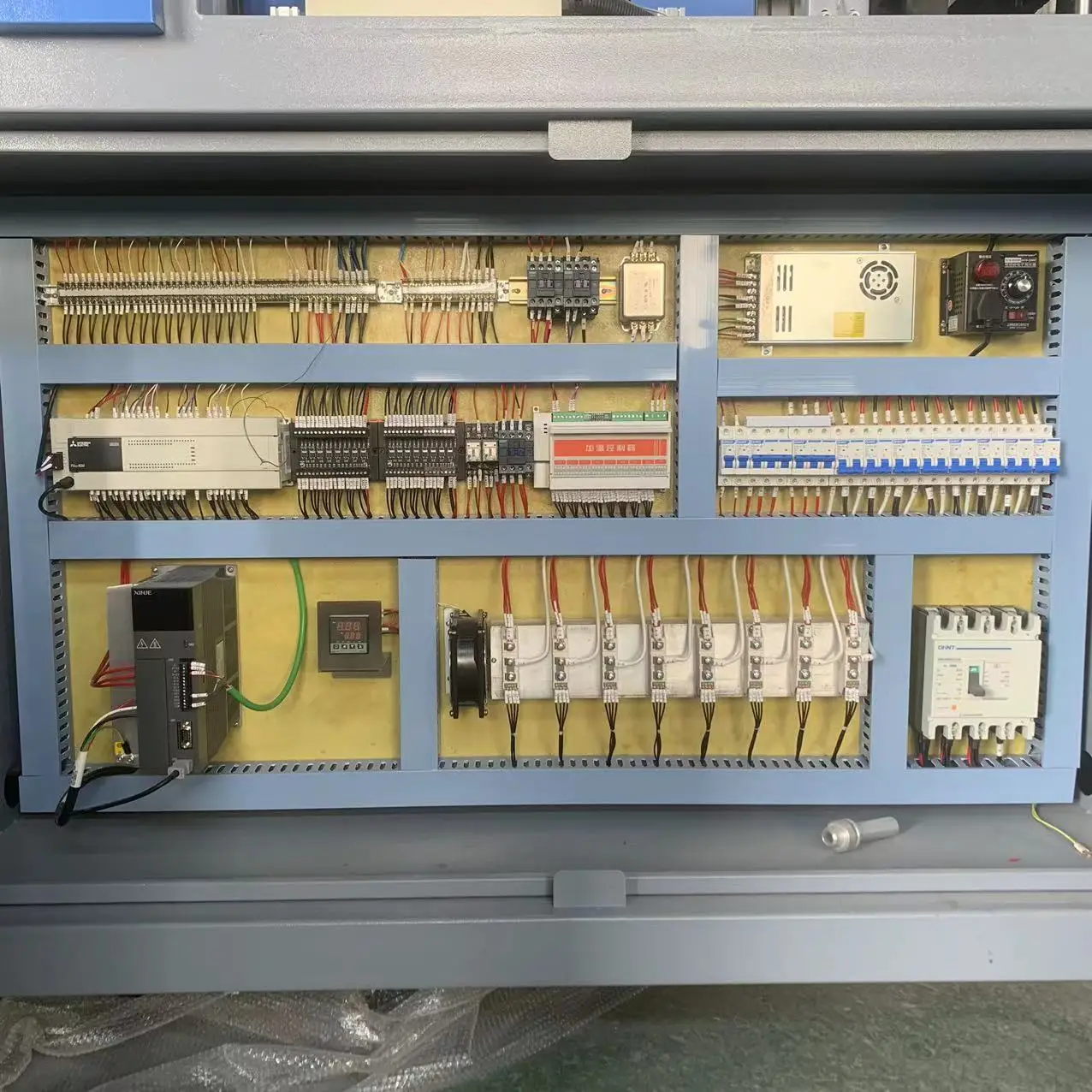

High specification power cabinet

Project Flow Chart

Packing&Shipping

We use bubble film and wrapping film for packing, which is safe in the container. We also support wooden case packing.

In terms of transportation, we have various options such as sea, air, land and express.

In terms of transportation, we have various options such as sea, air, land and express.

Company Profile

TAIZHOU WATON MACHINERY COMPANY LIMITED

WATON is a professional manufacturer of two-step straight line full electric high-speed PET blowing machine, located in Taizhou,Zhejiang Province. The team has more than 20 years of production practice experience, after years of research and development and improvement, TURBO series high-speed full servo automatic blowing machine single cavity output reached 1700 bottles per hour.

Product models are complete, suitable for a variety of different needs of customers.

Recommend Products

After Sales Service

after-sales service we offer

1.Your inquiry related to our product & price will be replied within 72 hours.

2.Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3.Working time: 8:30am ~5:30pm, Monday to Saturday.

4.Your business relationship with us will be confidential to any third party.

5.Good after-sales service offered, please get back to us if you got any questions.

FAQ

Q1: Are you a manufacturer or a trading company?

A1: We are a manufacturer, so we can provide you with machines of high quality and low price.

Q2: What guarantees or quality guarantees do you have if we buy your machine?

A2: We provide you with high quality machines and high quality after-sales service. We also offer a free two-year warranty on spare parts.

Q3: What are the advantages of servo control?

A3: 1. Accuracy

2. Quick response makes high speed possible

3. Low power consumption

4. Low noise

5. Hygienic, no oil leakage problem

Q4: When can I get my machine after payment?

A4: Delivery time is about 30-45 working days

A1: We are a manufacturer, so we can provide you with machines of high quality and low price.

Q2: What guarantees or quality guarantees do you have if we buy your machine?

A2: We provide you with high quality machines and high quality after-sales service. We also offer a free two-year warranty on spare parts.

Q3: What are the advantages of servo control?

A3: 1. Accuracy

2. Quick response makes high speed possible

3. Low power consumption

4. Low noise

5. Hygienic, no oil leakage problem

Q4: When can I get my machine after payment?

A4: Delivery time is about 30-45 working days