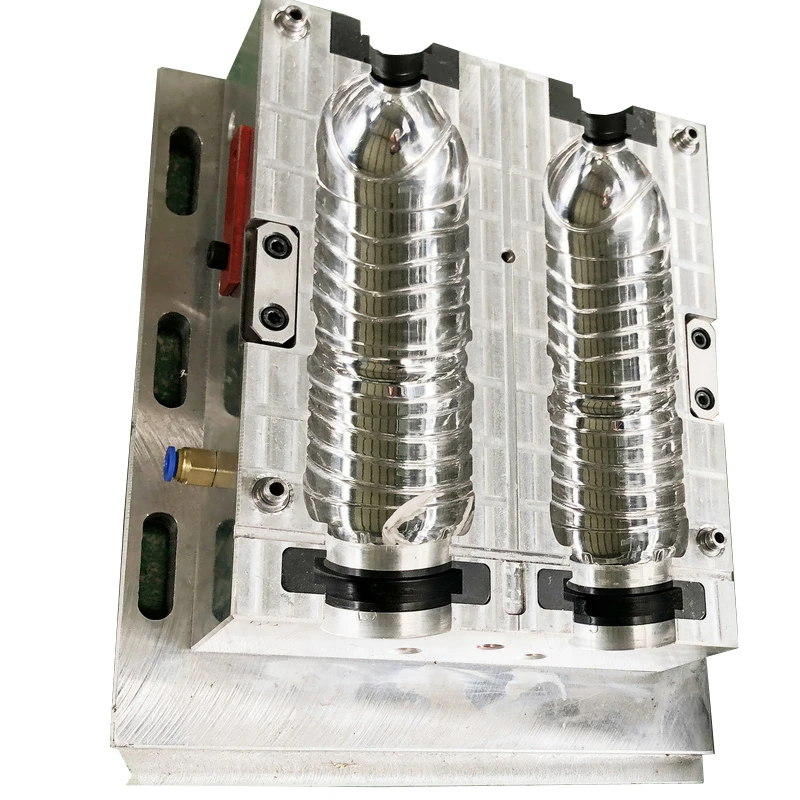

Cheapest Price Mould Customized By Factory Stretch Plastic PET Blowing Bottles Blow Mold Manufacturer

- Overview

- Related Products

Product Description

Technical introduction of Injection Mold

·The Moulds can be customized;

·Mold material can be S45C, ALUMINUM, P20, etc;

·Mold for automatic blowing machine need to supply us machine mold plate drawing;

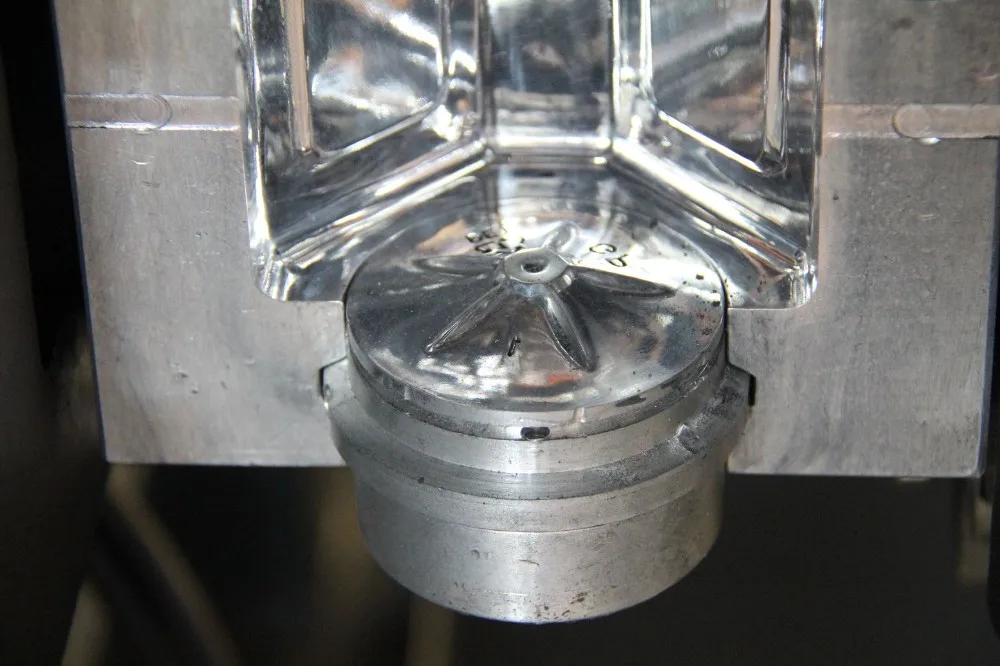

·After the mold is completed, it will be polished and oxidized;

·Single cavity,Multiple cavity or one mold with different products;

·All of the moulds can be well tested befre the shipments.

Features

With more than 20 years experience on PET Preform Mold design & manufacturing, WATON’s mold team has the ability to make up to 72-cavity Hot-runner Preform mold.

√Independent R&D team has obtained several National Patents on mold design.

√High quality steel material & new inserts material reduce cycle time 25-35%.

√Advanced CNC machines and techniques ensure the high precise preform wall thickness & weight.

√Valve-gate Hot-runner System for tailless preform production.

√Central Orientation Adjusting System minimizes Preform Eccentricity.

√Standard Inserts are changeable.

√Removable cooling pipes in cores could be easily cleaned.

√Fit for any brand Injection and blowing Machine.

With more than 20 years experience on PET Preform Mold design & manufacturing, WATON’s mold team has the ability to make up to 72-cavity Hot-runner Preform mold.

√Independent R&D team has obtained several National Patents on mold design.

√High quality steel material & new inserts material reduce cycle time 25-35%.

√Advanced CNC machines and techniques ensure the high precise preform wall thickness & weight.

√Valve-gate Hot-runner System for tailless preform production.

√Central Orientation Adjusting System minimizes Preform Eccentricity.

√Standard Inserts are changeable.

√Removable cooling pipes in cores could be easily cleaned.

√Fit for any brand Injection and blowing Machine.

Size Information

Cavitation |

Preform |

Mold Dimension |

Mold Weight

(kg)

|

Cycle |

||||||

Weight(g) |

Neck Size

(mm)

|

Height

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Time(sec) |

|||||

2(1*2) |

720 |

55 |

470 |

300 |

608 |

330 |

125 |

|||

4(2*2) |

720 |

55 |

490 |

480 |

730 |

440 |

130 |

|||

8(2*4) |

16 |

28 |

450 |

350 |

410 |

475 |

18 |

|||

12(2*6) |

16 |

28 |

600 |

350 |

415 |

625 |

18 |

|||

16(2*8) |

21 |

28 |

730 |

380 |

445 |

690 |

22 |

|||

24(3*8) |

28 |

28 |

770 |

460 |

457 |

1070 |

28 |

|||

32(4*8) |

36 |

28 |

810 |

590 |

515 |

1590 |

28 |

|||

48(4*12) |

36 |

28 |

1070 |

590 |

535 |

2286 |

30 |

|||