- Overview

- Related Products

Description of application effect

Introducing, the WATON’s 700-1000 BPH 2 cavity semi auto blow molding machine, the perfect solution for manufacturing high-quality bottles with ease. This cutting-edge machine is designed to increase production speed with efficiency, by producing up to 1000 bottles per hour.

Designed with two cavities, it enables users to create two identical bottles at once, doubling productivity. The machine uses a semi-automated process, reducing labor and energy costs, which makes it a reliable choice for businesses looking to reduce production costs while simultaneously increasing their output.

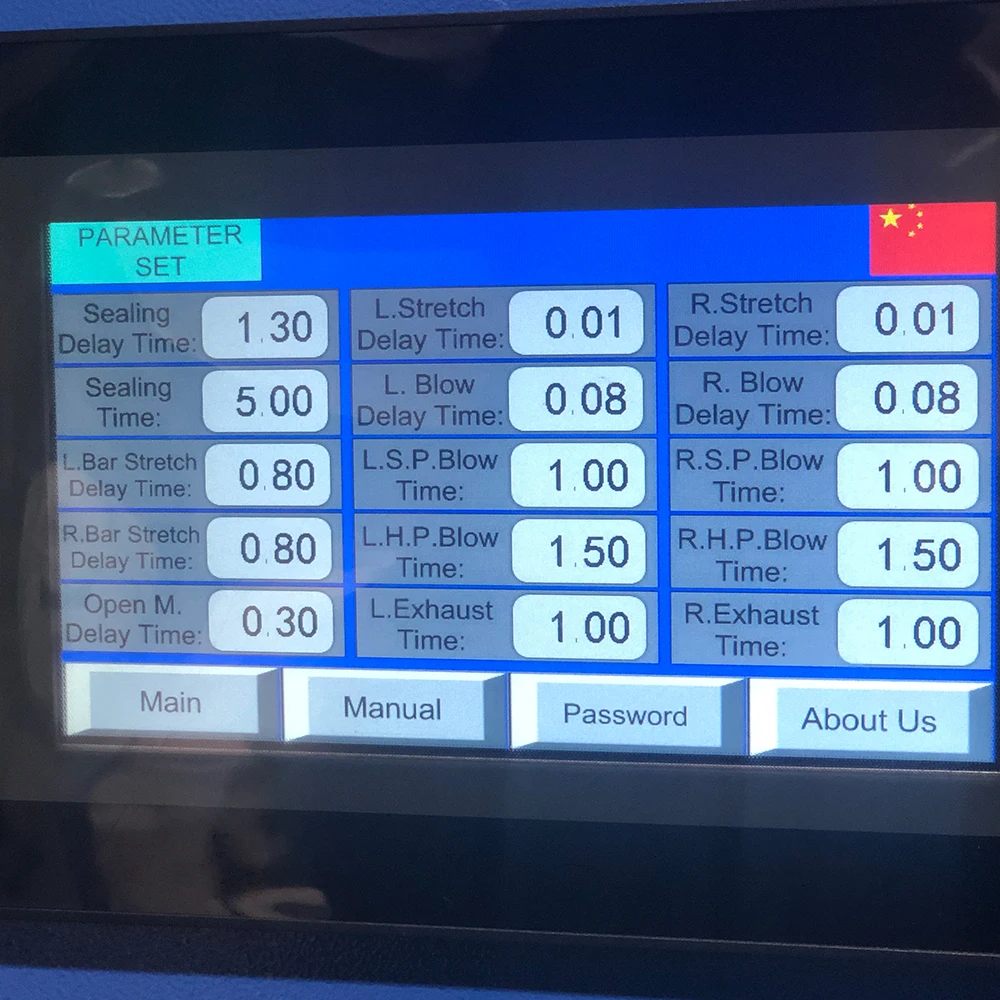

WATON's 700-1000 BPH 2 cavity semi auto blow molding machine possesses a high-quality control and monitoring system that aids in preventing defects. This advanced monitoring technology operates at multiple points during the process, and it ensures that the bottles produced are of consistent size, shape, and quality.

The machine is easy to operate, and it requires no professional training to control. It is built with a user-friendly operating system that simplifies the production process. The machine is configured to work with various materials such as polyethylene terephthalate (PET), which is a food-grade material. Thus, it makes it perfect for creating bottles for beverages, cosmetics, and personal care products.

The WATON’s 700-1000 BPH 2 cavity semi auto blow molding machine is manufactured with excellent durability, efficiency, and safety features. The machine operates at lower decibels, guaranteeing a noiseless environment that prevents noise-induced hearing loss.

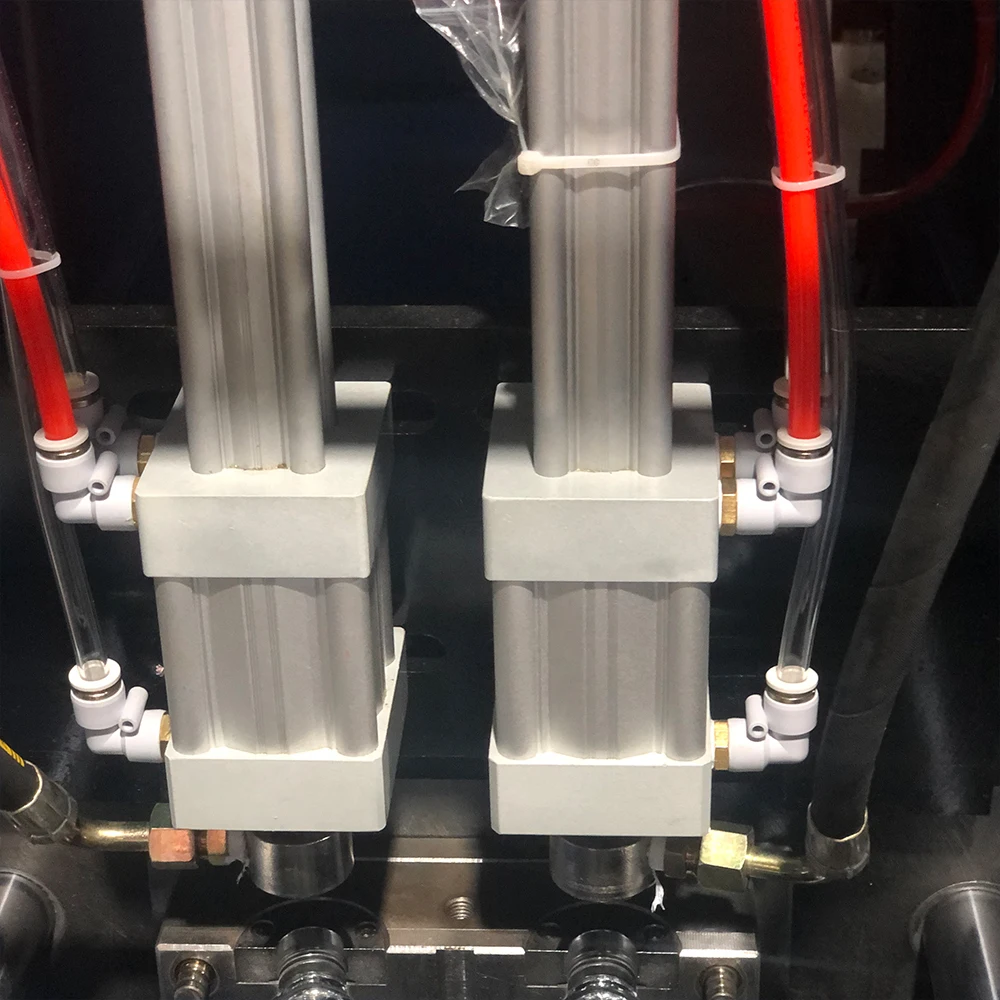

The machine is ergonomically designed, with a compact and lightweight structure that requires minimal floor space. This feature means the machine is suitable for factories and warehouses of different sizes. The machine's spare parts, critical components, and connectors are manufactured with top-notch precision, ensuring that any malfunction is solved promptly

Model |

MS-2L |

Theoretical Capacity |

700-1000 BPH |

Mold Cavities |

2 |

Neck Size |

18~48 mm |

Max. Volume |

3 Liter |

Advantages |

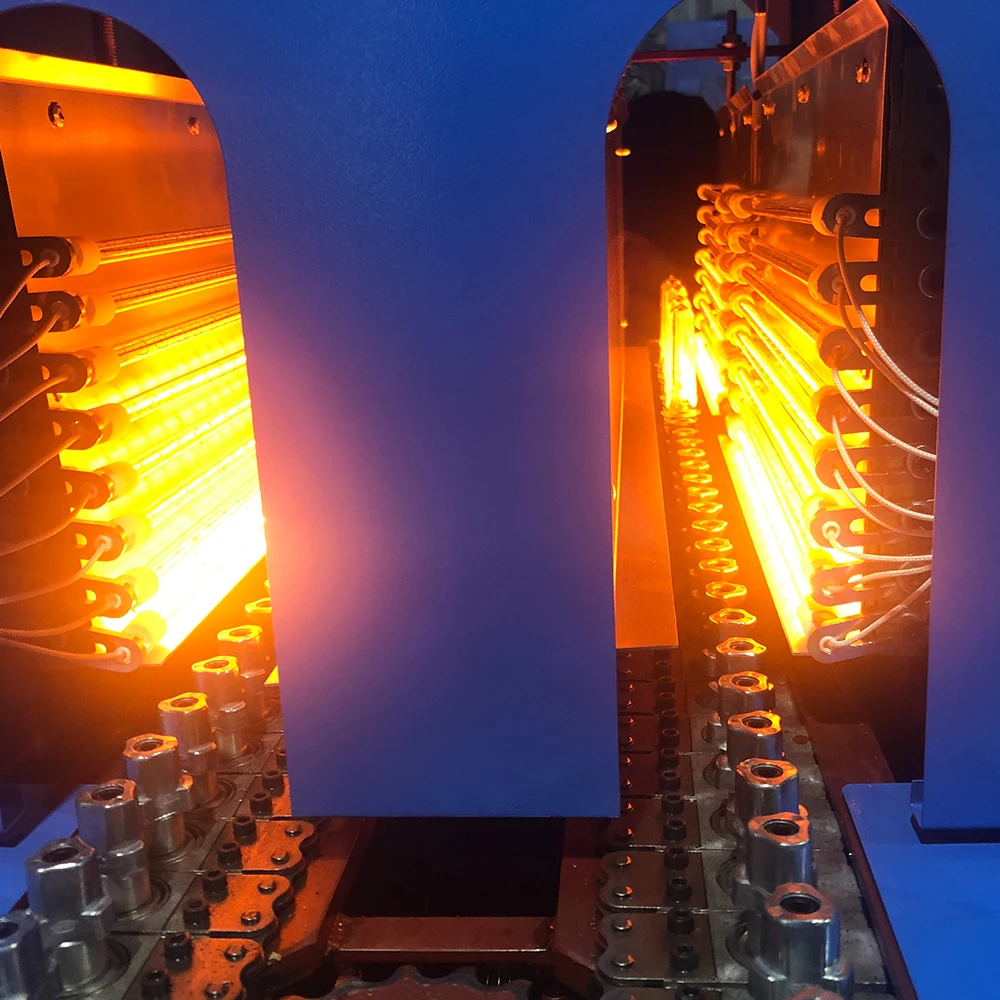

Suitable for various PET bottles from 100ml to 3L, wide range of application. Infrared heaters, independently adjustable, simple structure, stable running |

Each set of MS Series machine is composed by two parts: Bottle Blower and Infrared Preform Oven. Function of these two parts is:

Infrared Preform Oven: heat the PET preform to suitable soft condition for blowing;

Models |

MS-2L |

MS-2L4 |

MS-5L-1 |

MS-5L-2 |

MS-20L |

||

Theoretical Capacity(BPH) |

700~1,000 |

1,400~2,000 |

300~400 |

500~700 |

60~240 |

||

Mold Cavities |

2 |

4 |

1 |

2 |

1 |

||

Bottle |

Max. Neck Size |

100mm |

100mm |

110mm |

110mm |

55mm |

|

Max. Volume |

2000ml |

2000ml |

5000ml |

5000ml |

20000ml |

||

Max. Diameter |

105mm |

105mm |

180mm |

180mm |

280mm |

||

Max. Height |

330mm |

330mm |

350mm |

350mm |

500mm |

||

Main Machine Size |

1680*950*1980mm |

1 main machine |

1900*650*1580mm |

1900*800*1580mm |

2500*800*1900mm |

||

Heater Size |

1650*700*1700mm |

1 heater |

2100*600*1350mm |

2100*600*1350mm |

2600*700*1580mm |

||

Main Machine Weight |

1500KGS |

2500KGS |

1700KGS |

1700KGS |

2400KGS |

||

In terms of transportation, we have various options such as sea, air, land and express

A1: We are a manufacturer, so we can provide you with machines of high quality and low price

Q2: What guarantees or quality guarantees do you have if we buy your machine

A2: We provide you with high quality machines and high quality after-sales service. We also offer a free two-year warranty on spare parts

Q3: What are the advantages of servo control

A3: 1. Accuracy

2. Quick response makes high speed possible

3. Low power consumption

4. Low noise

5. Hygienic, no oil leakage problem

Q4: When can I get my machine after payment

A4: Delivery time is about 30-45 working days

A5: The delivery time is about 30-45 working days

1. Your inquiry related to our product & price will be replied within 72 hours.

2. Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3. Working time: 8:30am ~5:30pm, Monday to Saturday.

4. Your business relationship with us will be confidential to any third party.

5. Good after-sales service offered, please get back to us if you got any questions