- Overview

- Related Products

The WATON’s 5-Gallon Semi-Automatic Machine is the perfect solution for those looking to produce high-quality bottle products. The machine is designed to help you manufacture up to 80 bottles per hour with ease.

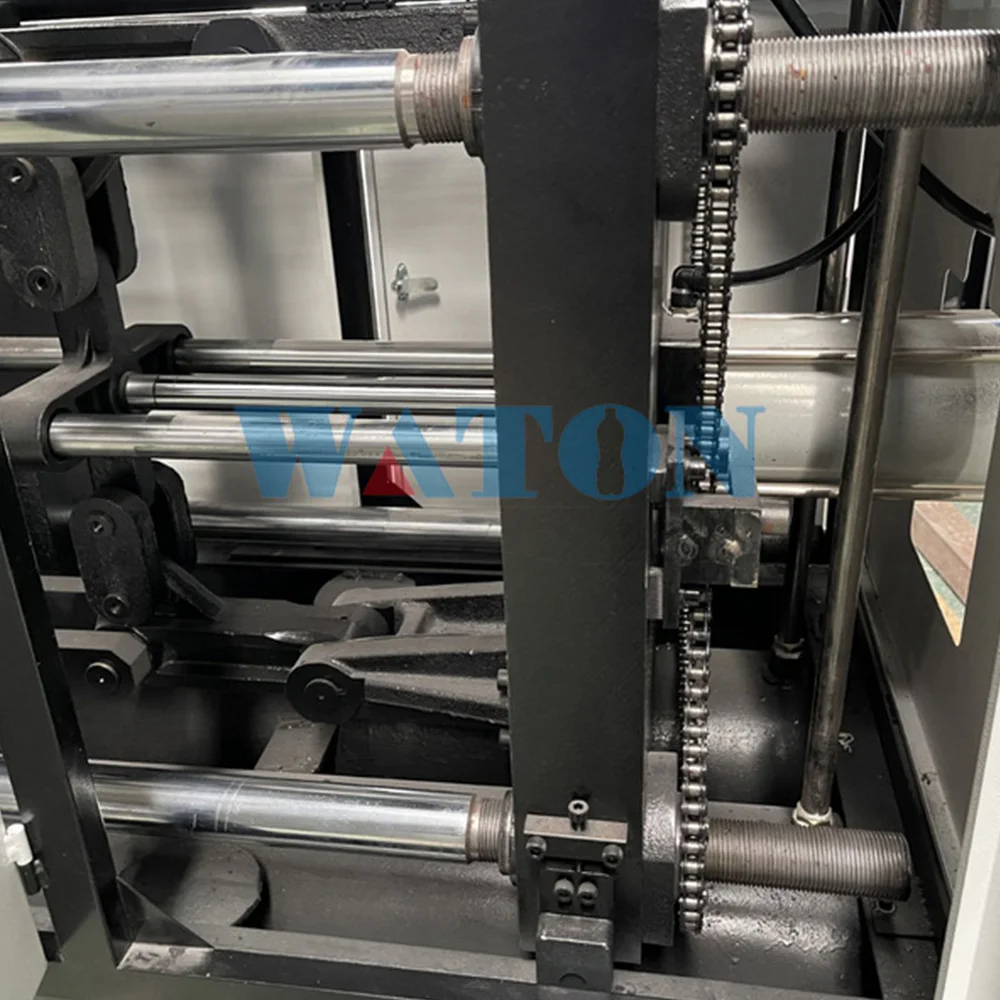

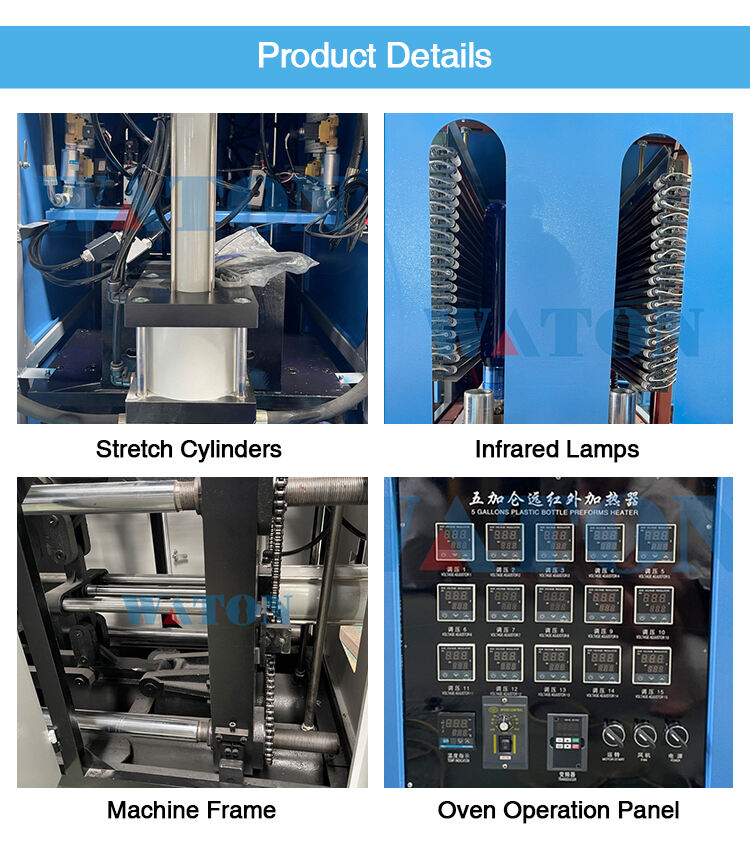

This machine is made with sturdy and reliable materials to ensure durability and longevity of use. The WATON’s 5-Gallon Semi-Automatic Machine is made with a high-quality stainless steel frame that is resistant to corrosion and rust, allowing for optimal performance for years to come.

The machine's semi-automatic design makes it easy to operate, and it comes with a user-friendly interface that requires minimal training to master. The machine's simple design means that there are fewer parts, making it easier to repair and maintain.

The WATON’s 5-Gallon Semi-Automatic Machine boasts an efficient and reliable heating system that allows for the efficient and accurate production of bottles. This heating system is equipped with an intelligent temperature-controlled system, which ensures that the machine maintains an optimal temperature throughout the production process.

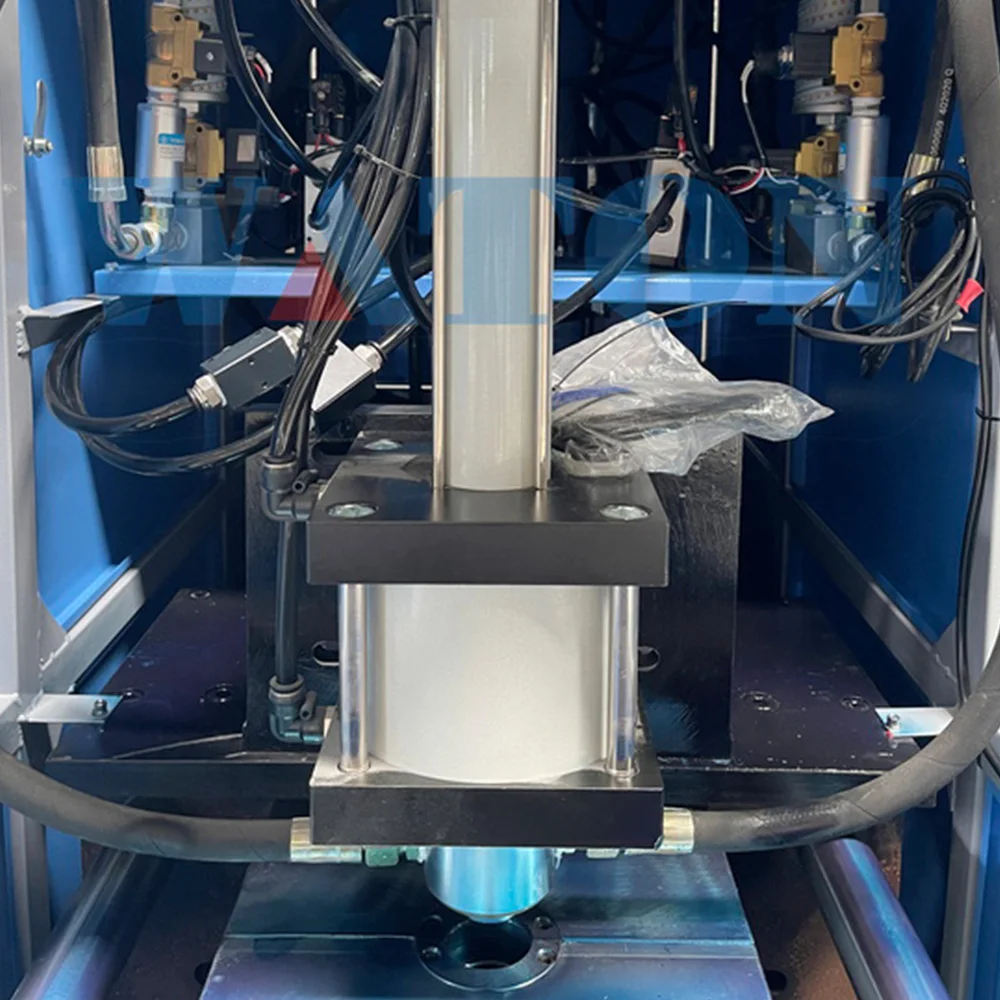

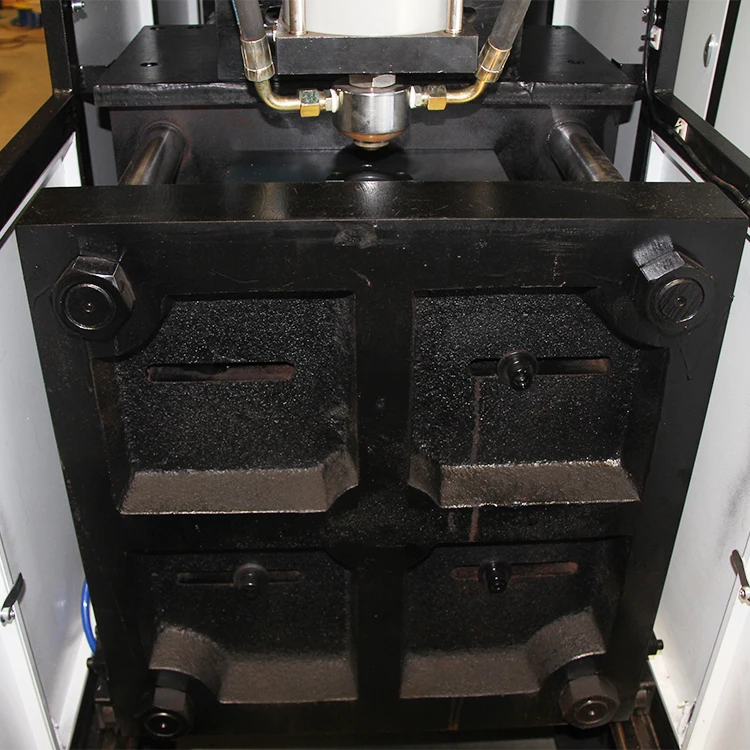

The machine's filling system is designed to be quick, efficient, and accurate. It is equipped with an advanced filling technology that can monitor and adjust the filling volume to ensure consistency in the final product. The filling system is also designed to be versatile, enabling it to fill a range of bottle sizes, including 3-gallon, 4-gallon, and 5-gallon bottles.

Additionally, the WATON’s 5-Gallon Semi-Automatic Machine is designed to be energy-efficient, consuming minimal power while in operation. The machine also features an automatic shut-off system that ensures the machine shuts down when not in use, further conserving energy

Machine Model |

MS-20L1 |

Production Capacity (BPH) |

60-120 |

Max. Bottle Size |

20000 ml |

Max. Bottle Diameter |

300mm |

Max. Bottle Height |

550 mm |

Mold Cavity |

1 cavities |

Heating Power |

50 KW |

General Power |

52 KW |

Blow Air |

2.5 – 4.0 MPa |

Drive Air |

0.8 – 1.2 MPa |

Main Machine Dimensions |

2500 * 800 * 1900 mm |

Oven Dimensions |

2600 * 700 * 1580 mm |

Main Machine Weight |

1450KGS |

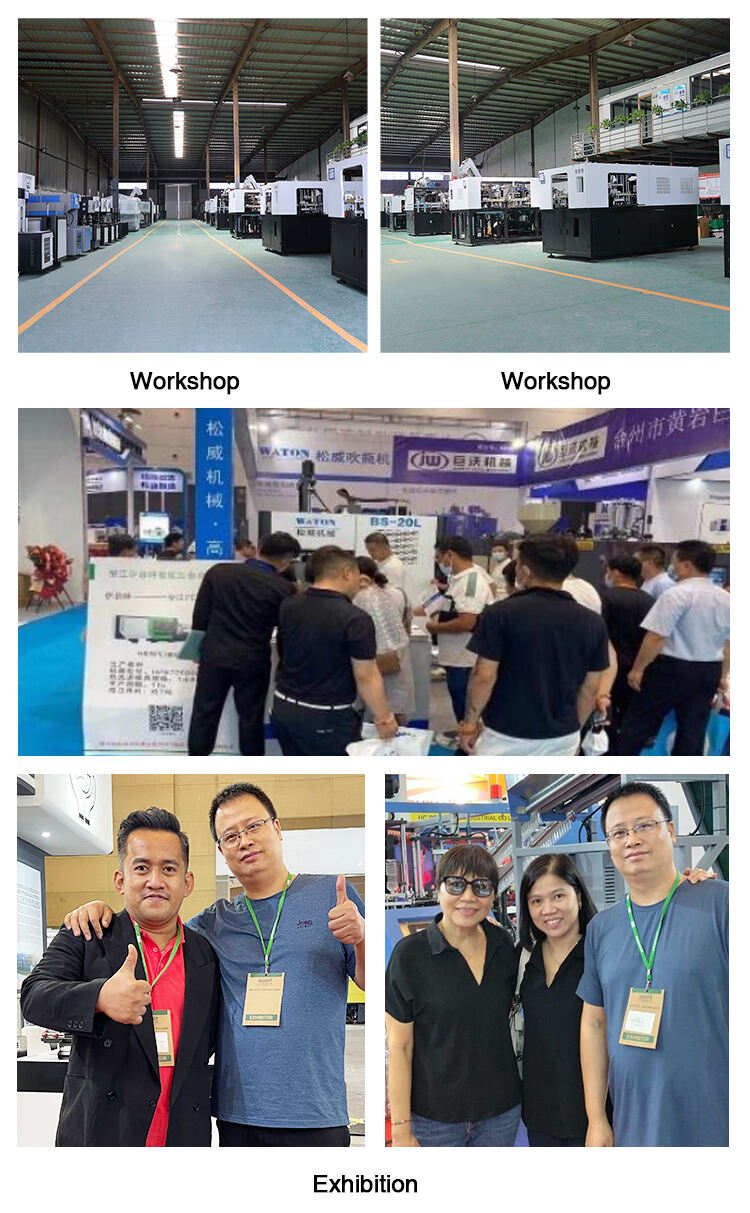

Q1: Where is your factory located? How can I visit there

A1: Our factory is located in Shangnian Industrial Area, Huang Yan, Taizhou City, Zhejiang Province, China. All our clients, from home or abroad, are warmly welcome to visit us! From Shanghai to our city, it takes 3.5 hrs by train, 45 mins by air

Q2: How long is the warranty period

A2: All of products have two years warranty

Q3: How can I install my machine when it arrives

A3: We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines

Q4: How long is the delivery time

A4: Under normal conditions, products are delivered within 45 working days

Q5: Where is the Shipping departure port

A5: Ningbo or shanghai port

Q6: What’s the payment

A6: T/T, L/C, Western Union, paypal

Q7: What are your main brand of electrical components

A7: Main parts in the products come from world famous manufacturers such as Mitsubishi, Schneider, Omron etc

Q8: Which country do you export your machines already

A8: We have exported Blow Molding Machine to USA, Canada, Australia, Mexico, Russia, Thailand, Indonesia, Vietam, Africa, the Middle East area etc

Q9. What products does your company offer by yourself

A9: We are specialized in PET Blow Molding Machine, PET Blow Mold, hot-runner PET Preform Mold

Q10: How about the quality of machine

A10: WATON have been focusing on quality issues, quality control from beginning to the end, and we will test machine strictly before packing and delivery.