- Overview

- Related Products

WATON

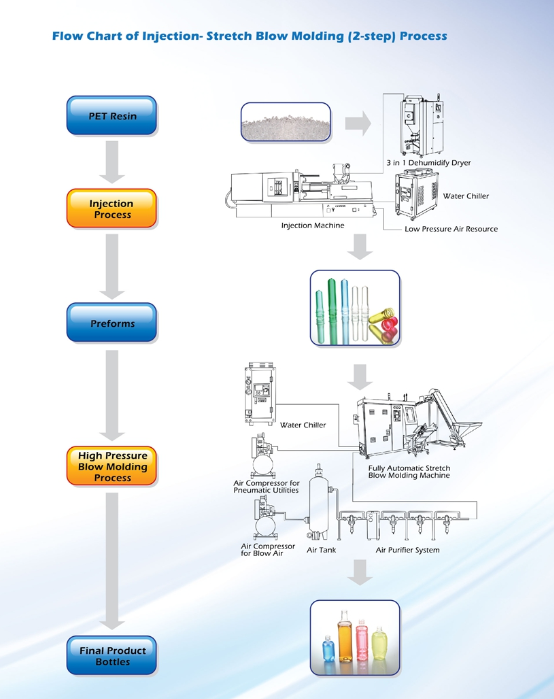

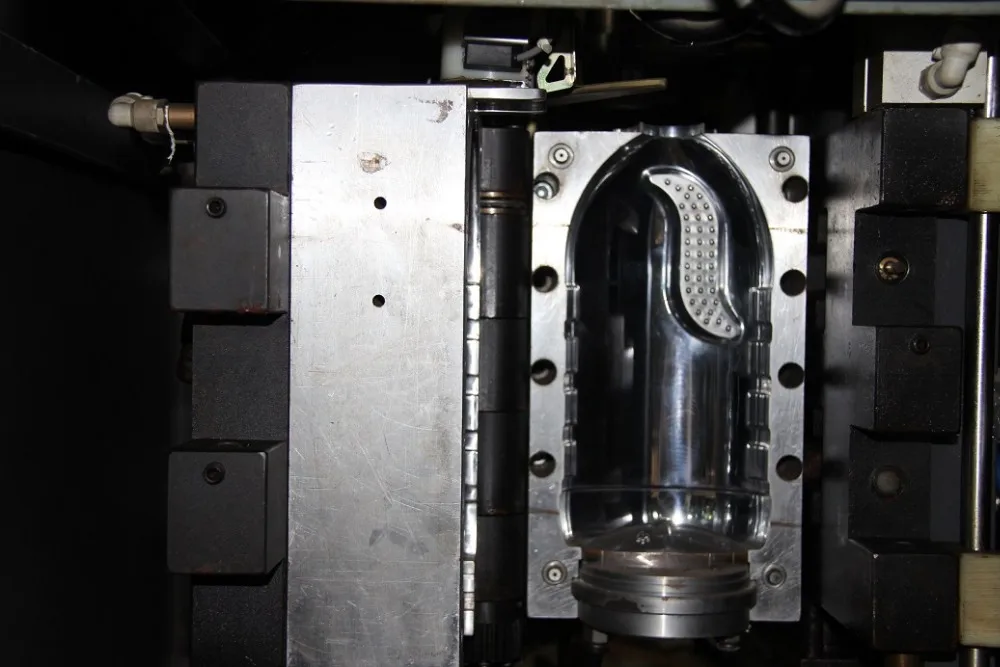

Introducing the brand-new product from - the 2 cavities 500ml plastic bottle blowing moulds. This is an innovative and practical mould that has been designed to provide an easy and efficient way of producing high-quality plastic bottles. Whether you are a professional in the plastics industry or a small business owner looking to expand your offerings, this mould is a must-have for anyone looking to manufacture high-quality plastic bottles.

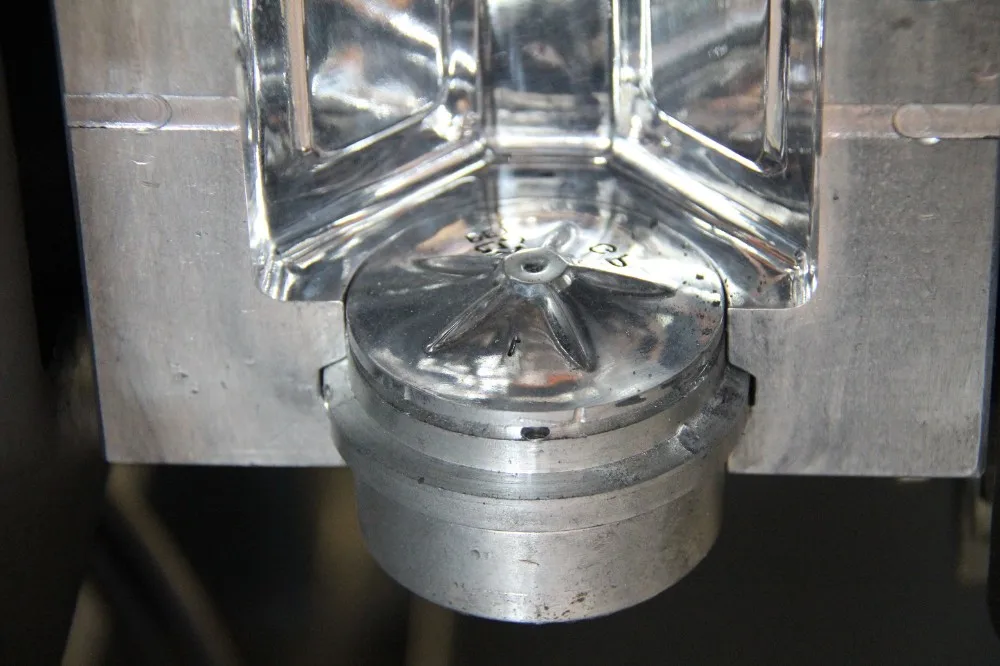

With its two cavities, this mould allows the user to produce two plastic bottles at the WATON same time, making it an ideal solution for mass production. The mould is made from high-quality materials, ensuring that it is durable and can stand up to high levels of wear and tear. This also means that the mould will last longer, making it a cost-effective solution for anyone who needs to produce a large number of plastic bottles.

One of the key features of this mould is its compatibility with a wide range of plastic materials, including PET, PP, and HDPE. This ensures that you can produce a variety of plastic bottles with ease, without having to worry about any compatibility issues. Additionally, the mould is easy to use and requires minimal maintenance, making it an ideal option for both professionals and beginners.

At WATON, we understand the importance of quality, which is why we have designed this mould to produce high-quality plastic bottles each time. The mould is equipped with various features that ensure that the bottles produced are uniform in shape and size, and free from defects such as air bubbles or uneven walls. This is essential for ensuring that the bottles are safe to use and will not leak or spill.

Cavitation |

Preform |

Mold Dimension |

Mold Weight

(kg)

|

Cycle |

||||||

Weight(g) |

Neck Size

(mm)

|

Height

(mm)

|

Width

(mm)

|

Thickness

(mm)

|

Time(sec) |

|||||

2(1*2) |

720 |

55 |

470 |

300 |

608 |

330 |

125 |

|||

4(2*2) |

720 |

55 |

490 |

480 |

730 |

440 |

130 |

|||

8(2*4) |

16 |

28 |

450 |

350 |

410 |

475 |

18 |

|||

12(2*6) |

16 |

28 |

600 |

350 |

415 |

625 |

18 |

|||

16(2*8) |

21 |

28 |

730 |

380 |

445 |

690 |

22 |

|||

24(3*8) |

28 |

28 |

770 |

460 |

457 |

1070 |

28 |

|||

32(4*8) |

36 |

28 |

810 |

590 |

515 |

1590 |

28 |

|||

48(4*12) |

36 |

28 |

1070 |

590 |

535 |

2286 |

30 |

|||