WATON MS-2L2 Model Populare Semi Automaticum Aqua Succus Lac PET Plasticum Butyrum Blower Stretc Conficiendi Adflatum Formandi Machina

- Conspectus

- Producta Relata

Introducimus vobis WATON's MS-2L2, model populare semi automaticum aqua succus lac PET plasticum flaschen blower stretch faciendum sufflando formandi machinam. Hoc productum est perfectum pro quocunque quaerit efficacem et fidem modum creandi plasticas flaschulas pro suis productis.

WATON's MS-2L2 est machina altissimae qualitatis quae est designata dare optimos possibiles resultatos. Est capax producendi latam varietatem diversarum magnitudinum flaschularum, a parvis succus flaschulis usque ad magnas aquae flaschulas.

Una ex parte characteristicis WATON MS-2L2 est designium semiautomaticum eius, quod significat esse facile ad usum et requirere minimum laboris manualis. Hoc facit id optima optione pro business parva ad mediocri, quae non habent magnum numerum operariorum.

Hoc machina est etiam mirabiliter flexibile, permitte te creare butyllos in latissima varietate formarum et magnitudinum. Hoc est gratia technologiae tractandae inclusae, quae permittit machinae trahere plasticum et formam desideratam creare.

WATON MS-2L2 potest producere usque ad 120 butyllos per horam, faciens id idoneum pro businessibus, quae necessitatem habent producere magnas quantitates butyllos regulariter. Hoc significat te posse competere cum demanda etiam in tempore frequentissimo anni.

Altera utilitas WATON MS-2L2 est quod est mirabiliter facile conservare. Factum est ex materialibus optimis, quae sunt descripta ut durent annos, et machina est facile purgare et reparare.

Exemplum |

MS-2L2 |

Capacitas Theoretica |

700-1000BPH |

Fossae Formae |

2 |

Cervix magnitudinis |

18-48mm |

Volumen Max. |

2000ml |

Praeponuntur |

Lata ambitio applicationis. Fornaces infrarubrae, singillatim adjustabiles, structura simplex, cursus stabilis |

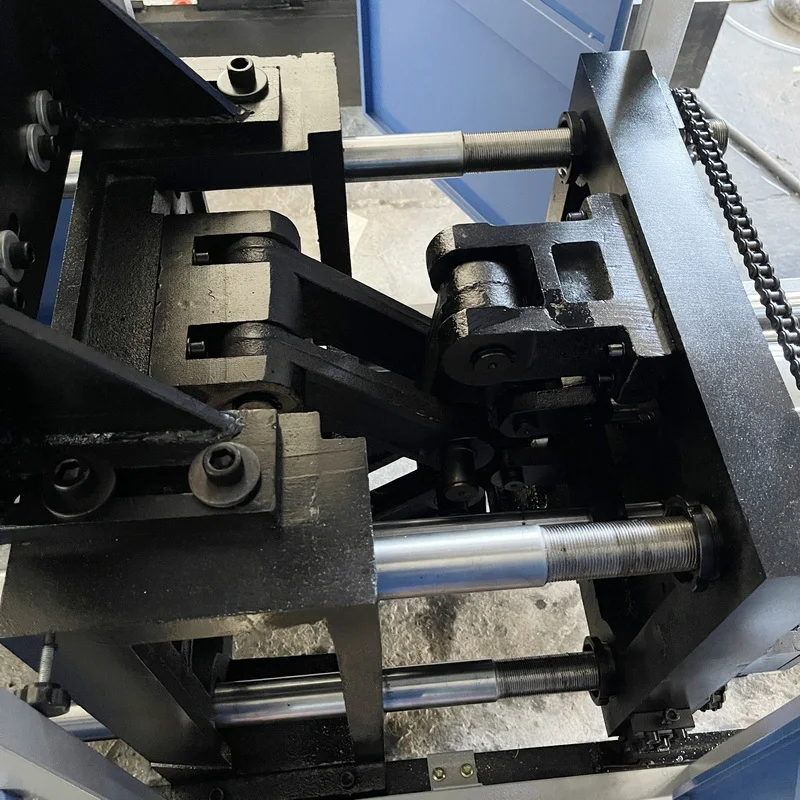

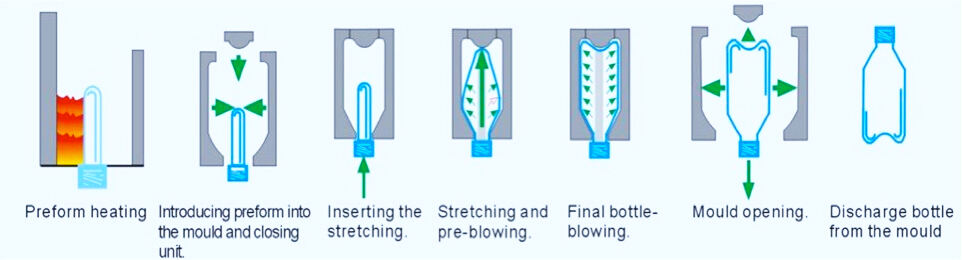

Unusquisque conjunctio machinarum seriei MS constat ex duabus partibus: Flator Fidelium et Praefornax Infrarubens. Functio harum duarum partium est:

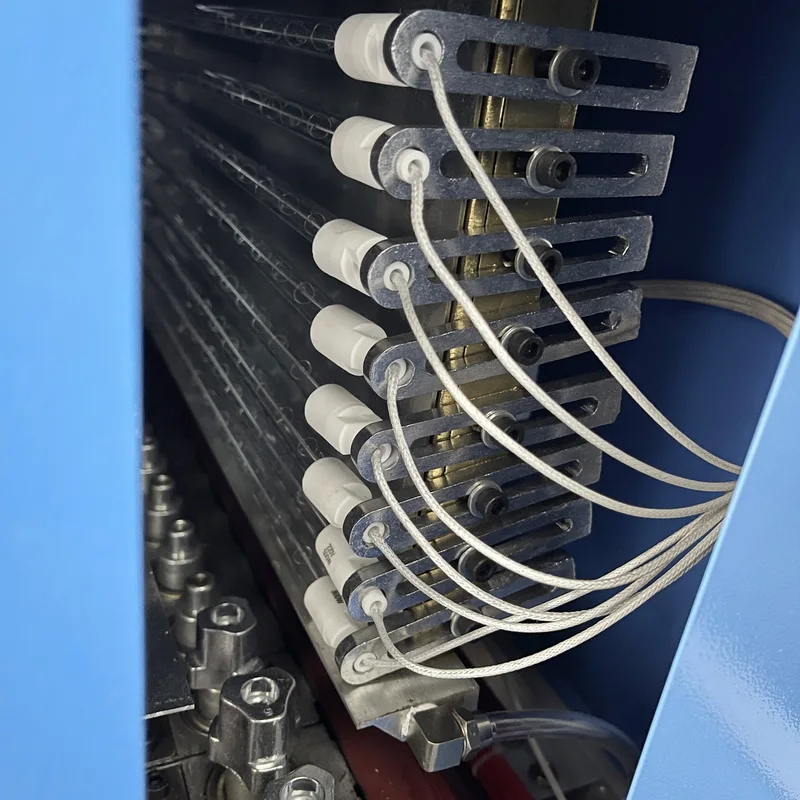

Praefornax Infrarubens: calefacere praeformam PET ad aptam molle statum pro sufflando;

Flator: facere totum processum sufflationis fidelium, includens sigillandum, extendendum, sufflando, exhalandum et motum formae sufflationis, quod regitur ab systemate controlis PLC progressivo

Systema Soporis Aeris Calidi cum Functione Praesoporis agit partem importantem in producendo albis qualitatis utiles, tollit apparitionem albam bottorum

Exempla |

MS-2L2 |

MS-2L4 |

MS-5L-1 |

MS-5L-2 |

MS-20L |

||

Capacitas Theoretica (BPH) |

800~1,000 |

1,600~2,000 |

350~400 |

700~800 |

60~240 |

||

Fossae Formae |

2 |

4 |

1 |

2 |

1 |

||

Butylicus |

Max. Largitudo Cervicis |

100mm |

100mm |

110mm |

110mm |

55mm |

|

Volumen Max. |

2000ml |

2000ml |

5000ml |

5000ml |

20000ml |

||

Diametrum Max. |

105mm |

105mm |

180mm |

180mm |

280mm |

||

Altitudinem Max. |

330mm |

330mm |

350mm |

350mm |

500mm |

||

Machina Principalis Magnitudo |

1680*950*1980mm |

2 machina principalis |

1900*650*1580mm |

1900*800*1580mm |

2500*800*1900mm |

||

Magnitudo Foculi |

1650*700*1700mm |

1 calefactor |

2100*600*1350mm |

2100*600*1350mm |

2600*700*1580mm |

||

Pondus Machinae Principalis |

1500kgs |

2500 libras |

1700kgs |

1700kgs |

2400KGS |

||

1. Responsum ad tuam interrogationem de nostro producto & pretio intra 72 horas dabitur.

2. Bene disciplinati & periti ministri respondebunt omnibus tuis interrogationibus lingua Anglica et Siniensi.

3. Tempus operativum: 8:30 ante meridiem ~5:30 post meridiem, a Lunae diei ad Sabbatum.

4. Nostri cum vobis commercii relatio erit confidentialis ad quemvis tertium.

5. Bonum post venditionem ministerium praebetur, responde quaeso nobis si quaestionum aliquam habeas.

Nostri Servitia & Robur

Q1: Num faber an mercator es

A: Fabri sumus ex Taizhou, itaque optima qualitas et optimus pretium tibi polliceri possumus.

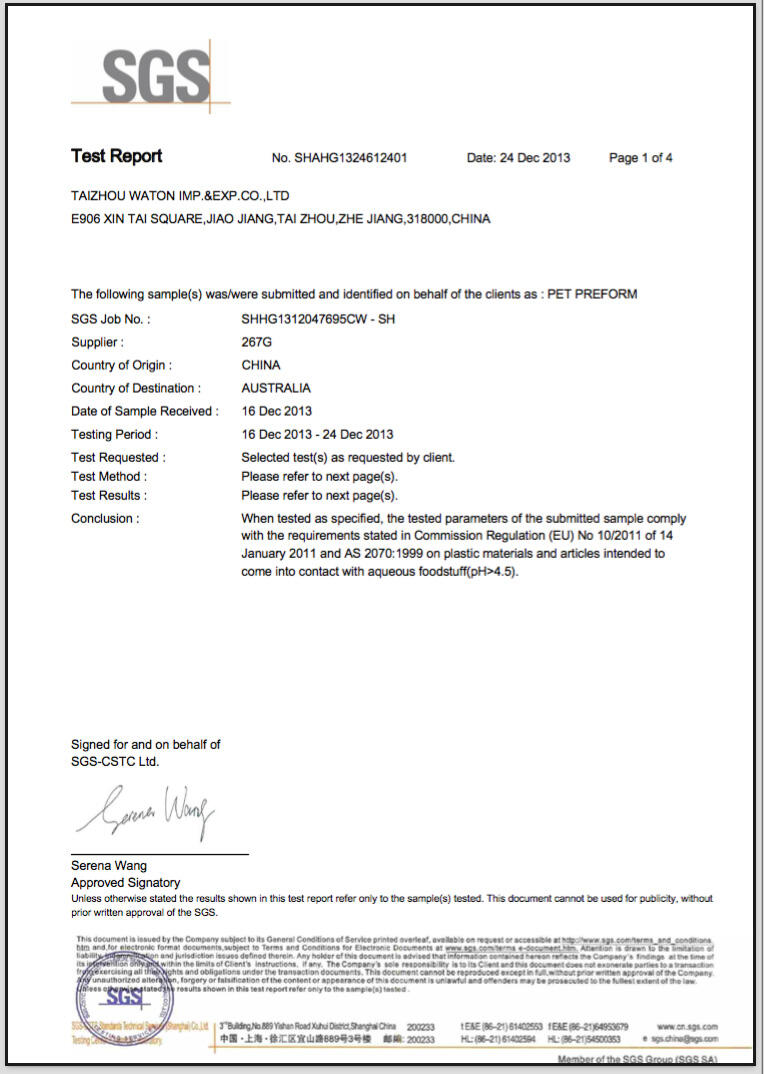

Q2: Quae tua fides aut warrantia qualitatis est si machinas tuas emimus

A2: Tibi praebemus machinas altae qualitatis cum alta post-qualitate servitii. Item habemus biennium warrantiam partium, gratis.

Q3: Quae est utilitas servocommandi

A3: 1. Praecisio

2. Celer reactio, facit altam velocitatem possibilem 3. Parva consumptio potentiae 4. Parvus sonus 5. Sanitas, sine problema olei effusione

Q4: Habitisne auxilium technicum postquam emimus vestras machinas

A4: Mittimus nostros technicos professionales ad fabricam tuam, qui te instruent et doceant quomodo machinas installare et conservare debeas quas emisti. Aut tibi adiuvent machinas reparare quando problemata habeant.

Q5: Quae post-venditionis servitia vestra societas offert

1. Responsum ad tuam interrogationem de nostro producto & pretio intra 72 horas dabitur.

2. Bene doctrinatus et experientia praeditus ministerii respondet omnibus interrogationibus tuis lingua Anglica et Siniensi. 3. Tempus operativum: 8:30am ~5:30pm, Lunae ad Saturni. 4. Relatio commercii tua cum nobis erit secreta adversus quamquam tertiam partem. 5. Bonum post-venditionis servitium praebetur, si quaestionum habes, responde nobis, quaeso.

Q6: Possumne visitare fabricam tuam et mittere team ad discendum et inspiciendum

A6:Ita, certe. Faciemus optime posse docendi te uti machina. Bene venies in visitandam fabricam nostram!

Q7: Quid sunt vestra praemia

A7: 1. Stabilia machina cursus cum nova technologia, pretio competitivo;

2. summa rank supportus technicus 3. Optima et prompta servitia

Q8: Ubi situatur fabrica tua? Quomodo possimus ibi visitare

A8: Fabrica nostra situatur in urbe Tai Zhou, provincia Zhe Jiang, China. A Shanghai ad urbem nostram, sumit 3.5horas per ferroviam, 45minutos per aerum.

Q9: Quid est terminus tuus de conglutinatione

A9: Propter novas dispositiones de fumigatione, machinas nobis cum pellicula bubbulosa et pellicula involutiva concludimus. Tuta est clausura in conteneatore. Possimus etiam casam ligneam facere. Quaedam regiones fumigationem pro cassi lignea postulant. Dependet a requisitione regionis tuae.

Q10: Quando potero machinam meam recipere postquam pecuniam solvi

A10: Tempus traditionis circiter 30-45 dies operativi sunt